Coating Inspection

In all major objects and structures that surround us, indoors, outdoors, underground, large or small, have manufactured surfaces featuring anti-rust, decorative or other coatings. Smallest imperfections of this protective layer could trigger long term problems and drive up repair costs. Preventing this damage using Elcometer adhesion testers will protect your investment in the long term.

Showing 1–60 of 129 results

-

Elcometer 1720

For testing the abrasion, wash ability, brush ability and resistance of a wide range of materials. $10,247.66 CAD – $11,709.44 CAD

$10,247.66 CAD – $11,709.44 CAD -

Amine Blush Test Elcometer 139

Elcometer 139

The presence of amine blush can cause inter-coat adhesion failures $705.30 CAD

$705.30 CAD -

Elcometer 1720 Washability & Abrasion Testers

For testing the abrasion, wash ability, brush ability and resistance of a wide range of materials $427.33 CAD – $1,301.36 CAD

$427.33 CAD – $1,301.36 CAD -

Digital Surface Profile Gauge with integrated probe

Elcometer 224 Integral

Ideal for single-handed operation as the wide footprint of the internal probe provides greater stability $1,169.98 CAD – $1,475.61 CAD

$1,169.98 CAD – $1,475.61 CAD -

Digital Surface Profile Gauge with attachable probes

Elcometer 224 with attachable probes

Separate adapted to harsh field conditions $791.05 CAD – $1,125.72 CAD

$791.05 CAD – $1,125.72 CAD -

Pulsed DC Holiday Detector

Elcometer 280

Ideal for performing the holiday test procedure on large surfaces and pipelines $5,158.40 CAD – $6,759.86 CAD

$5,158.40 CAD – $6,759.86 CAD -

Elcometer 266 Porosity testing gauge

Elcometer 266

Ideal for inspecting coatings on pipelines and other protective coating $719.13 CAD – $2,102.08 CAD

$719.13 CAD – $2,102.08 CAD -

Testex Press-O-Film Tape Thickness Gauge

Elcometer 124

Measure the surface profile of your blasted substrate $645.84 CAD

$645.84 CAD -

$6,905.07 CAD – $8,798.33 CAD

-

Calibration Verification Tiles

Set of 3

For the field or laboratory verification of instrument accuracy $1,009.55 CAD

$1,009.55 CAD -

Automatic Pull-Off Adhesion Tester

Elcometer 510

Non destructively measure the strength of the bond between the coating and the substrate in the field and / or lab $4,430.97 CAD – $5,740.63 CAD

$4,430.97 CAD – $5,740.63 CAD -

$1,228.06 CAD – $2,649.73 CAD

-

$907.22 CAD – $1,228.06 CAD

-

Digital Powder & Paint Gauge

Elcometer 415

Ideal for measuring paint or powder on both steel and aluminum surfaces such as car body panels or in a powder shop $864.34 CAD – $1,518.48 CAD

$864.34 CAD – $1,518.48 CAD -

Digital Delta T Hygrometer

Elcometer 309

Designed for hot weather where the surface temperature exceeds the paint manufacturer’s specifications $864.34 CAD

$864.34 CAD -

$1,373.27 CAD – $1,518.48 CAD

-

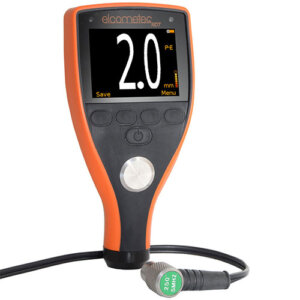

Ultrasonic Material Thickness Gauge with Transducer

MTG2

Suitable for use in the harshest of environments $2,102.08 CAD

$2,102.08 CAD -

Ultrasonic Material Thickness Gauge

MTG8

Ideal for users who are measuring a variety of materials or thicknesses $3,702.16 CAD – $4,430.97 CAD

$3,702.16 CAD – $4,430.97 CAD -

Digital Coating Thickness Gauge

Elcometer 456 Separate

Take individual dry film thickness readings or rapidly scan large surface areas $762.01 CAD – $1,883.58 CAD

$762.01 CAD – $1,883.58 CAD -

Whirling Hygrometer

Elcometer 116A

Designed to determine the dewpoint and relative humidity at any given time $208.83 CAD

$208.83 CAD -

Digital Hygrometer

Elcometer 308

Fast measurement of the two critical climate parameters within coatings: Delta T & RH $936.26 CAD

$936.26 CAD -

Dust Tape Roller

Elcometer 145

Assess the quantity and size of dust particles on surfaces prepared for painting $748.18 CAD

$748.18 CAD -

$3,454.61 CAD

-

Cross Hatch Adhesion Tester

Elcometer 1542 Kits

Ideal for evaluating coatings up to 250µm (9.8mils) on flat surfaces $645.84 CAD – $1,228.06 CAD

$645.84 CAD – $1,228.06 CAD -

Chloride, Sulphate & Nitrate Kit

Elcometer 134CSN

Accurately measure surface chloride, sulphate and nitrate ions in minutes $2,772.81 CAD

$2,772.81 CAD -

$1,082.85 CAD

-

$196.38 CAD

-

$354.04 CAD

-

Infrared Digital Laser Thermometer

Elcometer 214

Accurately measures the surface temperature of non-reflective materials using infrared technology $340.21 CAD

$340.21 CAD -

$311.16 CAD

-

Dual Element Thickness Transducer

Dual Element Thickness Transducer

Designed for applications on glass, aluminium, and titanium applications $791.05 CAD – $907.22 CAD

$791.05 CAD – $907.22 CAD -

Pinholes Detectors

Elcometer 270

monitor the integrity of the protective coating from its initial application to the end of its service life. $719.13 CAD – $1,082.85 CAD

$719.13 CAD – $1,082.85 CAD -

$500.63 CAD

-

$500.63 CAD

-

$572.54 CAD

-

$688.71 CAD

-

$354.04 CAD

-

$354.04 CAD

-

$791.05 CAD – $936.26 CAD

-

$936.26 CAD – $1,082.85 CAD

-

$165.95 CAD

-

$165.95 CAD

-

$114.78 CAD

-

$78.83 CAD

-

$208.83 CAD

-

$121.70 CAD

-

$427.33 CAD – $684.56 CAD

-

$92.66 CAD

-

$179.78 CAD

-

$266.91 CAD

-

$392.76 CAD

-

$543.50 CAD

-

$266.91 CAD

-

Manual Pull-Off Adhesion Tester

Elcometer 106

For site-testing paint or plasma spray on bridge decking, coatings on steel, aluminum, concrete, etc. $1,748.05 CAD – $1,810.28 CAD

$1,748.05 CAD – $1,810.28 CAD -

$2,232.08 CAD

-

$4,430.97 CAD – $4,867.98 CAD

-

$427.33 CAD

-

$572.54 CAD

-

$66.38 CAD – $688.71 CAD

-

$165.95 CAD

Need larger choice of equipment for a bigger project?

Our parent website geneq.com, can offer a unique price per any combination of items you choose, and the best shipping method for weighty items. We work with the biggest names in the industry since 1972!

0 items

0 items