Non-destructively measure the strength of the bond between the coating and the substrate

Elcometer 500 features state-of-the-art electronics that accurately, repeatably and reliably measures up to 9mm (355mils) coatings on concrete, or other similar surfaces.

Hand-held, waterproof, ruggedly designed, it has intuitive menu in multiple languages, ideal for the laboratory or field use. Test with confidence on flat or curved surfaces using the following simple procedure: Glue dollies to the coating and once it has cured, use the adhesion tester to pull the coating off the surface to assess adhesion.

Elcometer 510 is similar in operation to the Elcometer 506 except it is operated automatically and not manually.

Understanding Pull-off adhesion testing – Elcometer 510 and other devices

When testing coatings on low bond strength substrates such as concrete, wood or other fibrous materials, a larger surface area of dolly (50mm) is required to provide accurate, repeatable and reproducible results.

Using the smaller area dolly (10mm) on tiny parts or curved surfaces ensures accurate and consistent results.

Elcometer 510

- The automatic hydraulic pump ensures smooth and continuous pressure application for consistent, repeatable results

- Set adjustable pull rates @ 0.04, 0.08, 0.12, 0.16, 0.20 MPa/s(5, 8, 16, 24, 30psi/s)

- Can be used with 10, 14.2, 20 and 50mm diameter dollies

- User-definable limits with unique pressure hold and release function

- User-definable measurement range with an accuracy of ±1% of full scale:

- 10mm dolly: 14400psi (100MPa)

- 14.2mm dolly: 7200psi (50MPa)

- 20mm dolly: 3600psi (25 MPa)

- 50mm dolly: 580psi (4MPa)

- Dust and water-resistant rugged design to IP64

- Interchangeable units: MPa, psi, Nmm2 and N

- A range of standard and thin substrate actuator skirts (compatible with Elcometer 506) available for testing coatings on thick, thin, flat or convex substrates

- Store up to 60 readings

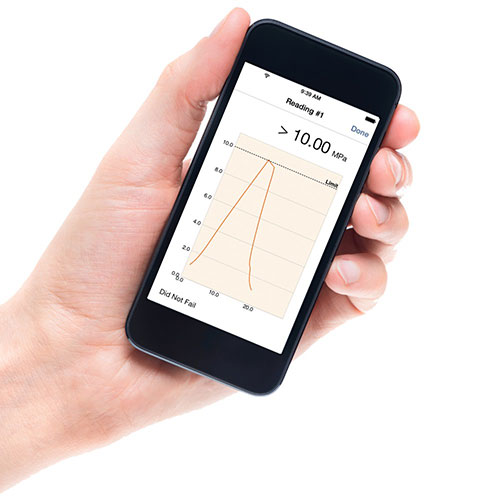

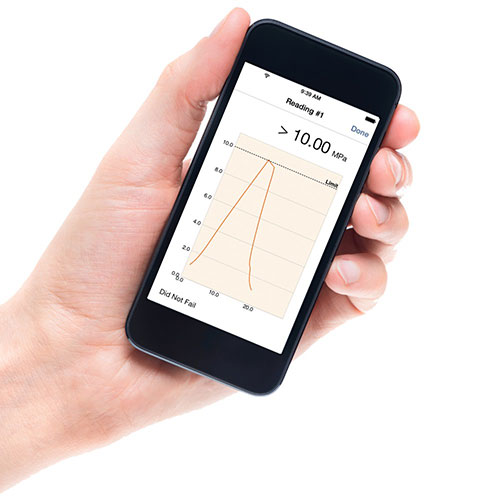

- USB and Bluetooth® data output – Compatible with ElcoMaster™ App for iPhone, iPod, iPad and Android mobile devices

Pull-off adhesion tester specifications

| Adhesion | ||||

| Product Features | ■ Standard | □ Optional | ||

| Model S | Model T | |||

| Repeatable & reproducible measurements | ■ | ■ | ||

| Easy to use menu structure; in multiple languages | ■ | ■ | ||

| Tough, impact, waterproof & dust resistant; equivalent to IP64 | ■ | ■ | ||

| Bright LCD colour screen; with ambient light sensor | ■ | ■ | ||

| Scratch & solvent resistant display; 2.4” (6cm) TFT | ■ | ■ | ||

| Calibration certificate | ■ | ■ | ||

| 2 year gauge warranty | ■ | ■ | ||

| Automatic rotating display; 0°, 180° | ■ | ■ | ||

| Data output via USB (Live readings – and batch) | ■ | ■ | ||

| Data output via Bluetooth ® | ■ | |||

| PC command; start & stop gauge from a PC with live readings (USB only) | ■ | |||

| Switchable Units (MPa, psi, N, N/mm -2) | ■ | ■ | ||

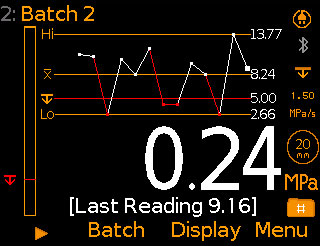

| On-Screen Statistics (η, x-, σ, hi, lo, COV, N>hi limit ǂ) | ■ | ■ | ||

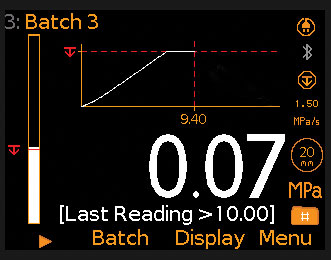

| Pull Rate Indicator | ■ | ■ | ||

| Trend Graph | ■ | ■ | ||

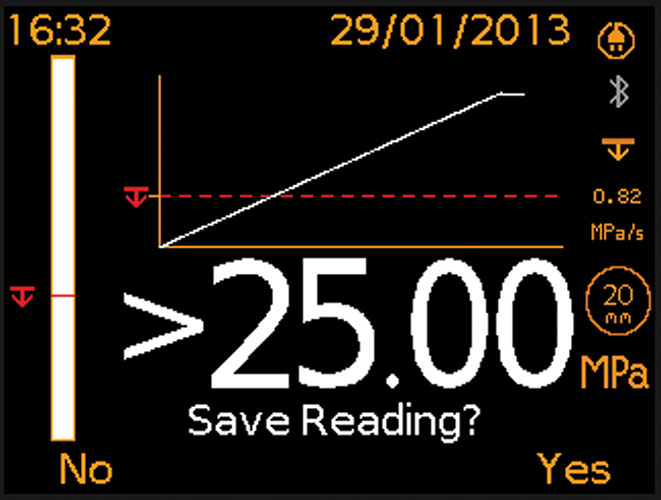

| Pull Rate Graph (Load v Time) | ■ | |||

| Interchangeable Dolly Selection; 10, 14.2, 20 & 50mm | ■ | ■ | ||

| User Selectable Pull Rates; (Model S & Model T Standard Mode) 10mm: 1.00, 2.00, 3.00, 4.00, 5.00 MPa/s 125, 200, 400, 600, 725psi/s 14.2mm: 0.4, 0.7, 1.4, 2.0, 2.5 MPa/s 60, 100, 200, 300, 360psi/s 20mm: 0.2, 0.3, 0.7, 1.0, 1.2 MPa/s 30, 50, 100, 150, 180psi/s 50mm: 0.04, 0.08, 0.12, 0.16, 0.20 MPa/s 5, 8, 16, 24, 30psi/s |

■ | ■ | ||

| User Selectable Pull Rates; (Model T Advanced Mode) | ||||

| 10mm: 0.40 – 5.60 MPa/s | 58 – 812psi/s | in 0.1MPa / 1psi steps | ||

| 14.2mm: 0.20 – 2.80 MPa/s | 29 – 403psi/s | in 0.1MPa / 1psi steps | ■ | |

| 20mm: 0.10 – 1.40 MPa/s | 15 – 203psi/s | in 0.1MPa / 1psi steps | ||

| 50mm: 0.02 – 0.22 MPa/s | 2 – 32psi/s | in 0.01MPa / 0.1psi steps | ||

| User Selectable Limit & Limit Hold Time | ■ | |||

| Gauge Memory; maximum number of readings | 60 | 60,000* | ||

| Number of Batches (Alpha Numeric – Model T) | 1 | 2,500 | ||

| Attribute Modes to meet National & International Standards | ■ | |||

| Display Modes | ||||

| Readings, Selected Stats & Run Chart (last 20 readings) | ■ | ■ | ||

| Pull Rate Graphs | ■ | |||

| Batch Review | ■ | |||

| Power; Battery (B), AC Mains Power (M) | B | B, M | ||

| USB Cable & ElcoMasterTM 2.0 CD | ■ | ■ | ||

| Power Cable with Multi International Plug Adaptor (UK, EU, US, AUS) | ■ | |||

| Plastic Transit Case | ■ | ■ | ||

| Date & Time | ■ | |||

| In Field Adhesion Calibration Verification Mode | ■ | ■ | ||

| ǂModel T only. | ||||

| * When ‘Rate Graph’ is enabled, the number of readings that can be stored depends on the graph resolution selected | ||||

| Part Number | Description | Certificate | ||||

| F510-20S | Elcometer 510 Model S Automatic Adhesion Gauge; 20mm Kit | ● | ||||

| F510-20T | Elcometer 510 Model T Automatic Adhesion Gauge; 20mm Kit | ● | ||||

| F510-50S | Elcometer 510 Model S Automatic Adhesion Gauge; 50mm Concrete Kit | ● | ||||

| F510-50T | Elcometer 510 Model T Automatic Adhesion Gauge; 50mm Concrete Kit | ● | ||||

| Pressure Accuracy | ±1% of full scale | Pull Rate Accuracy | ±(2.5% + 0.3 seconds) | |||

| Pressure Resolution | 0.01MPa (1 psi) | Pull Rate Resolution | 0.01MPa/s (1psi/s) | |||

| Dolly Diameter | 10mm (0.39”) | 14.2mm (0.56”) | 20mm (0.76”) | 50mm (1.96”) | ||

| Operating Range | 8 to 100 MPa (1200 to 14400 psi) |

4 to 50 MPa (600 to 7200 psi) |

2 to 25 MPa (300 to 3600 psi) |

0.3 to 4 MPa (50 to 580 psi) |

||

| Pull Rate Range | 0.4 – 5.6MPa/s (58 – 812psi/s) |

0.2 – 2.8MPa/s (29 – 403psi/s) |

0.1 – 1.4MPa/s (15 – 203psi/s) |

0.02 – 0.22MPa/s (2 – 32psi/s) |

||

| Gauge Dimensions | 260 x 100 x 66mm (6.3 x 3.9 x 2.6”) | |||||

| Actuator Height1 | 85mm (3.4”) | 85mm (3.4”) | 85mm (3.4”) | 110mm (4.3”) | ||

| Instrument Weight1 | 2.9kg (6.4lb) | 2.9kg (6.4lb) | 2.9kg (6.4lb) | 3.1kg (8.3lb) | ||

| Kit Weight | – | – | 6.1kg (13.5lb) | 7.3kg (16.1lb) | ||

| Power Supply | 8 x AA NiMH/Alkaline batteries (16 rechargeable batteries supplied complete with charger) or AC mains power (Model T only) |

|||||

| Battery Life | ~200 pulls per charge up to 25MPa (3600psi) at 1MPa/s (150psi/s), recharge time <5 hours | |||||

| Packing List: | Elcometer 510 Adhesion Tester with 20mm dollies (x10), standard skirt for 20mm dollies, 20mm dolly | |||||

| 20mm Kit | cutter handle, 20mm dolly cutter, Araldite standard two part epoxy adhesive (2 x 15ml tubes), abrasive | |||||

| pad, shoulder harness, carry case, 16 x AA MiMH rechargeable batteries & charger (UK, EU, US, AUS), | ||||||

| mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster TM CD & USB cable, calibration certificate | ||||||

| and operating instructions. | ||||||

| Packing List: | Elcometer 510 Adhesion Tester with 50mm dollies (x6), standard skirt for 50mm dollies, 50mm dolly | |||||

| 50mm Kit | cutter arbor, 50mm dolly cutter, Araldite standard two-part epoxy adhesive (2 x 15ml tubes), abrasive | |||||

| pad, shoulder harness, carry case, 16 x AA MiMH rechargeable batteries & charger (UK, EU, US, AUS), | ||||||

| mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster TM CD & USB cable, calibration certificate | ||||||

| and operating instructions. | ||||||

| Accessories | ||||||

| Dolly Diameter | Pack of 10† | Pack of 100 | Standard Skirt | Thin Substrate Skirt | ACrubttoerr Handle/ | Dolly Cutter |

| 10mm (0.39”) | T5100010AL-10 | T5100010AL-100 | T9991420S | – | – | – |

| 14.2mm (0.56”) | T9990014AL-10 | T9990014AL-100 | T9991420S | T9990014T | T9991420H | T9990014CT |

| 20mm (0.76”) | T9990020AL-10 | T9990020AL-100 | T9991420S | T9990020T | T9991420H | T9990020CT |

| 50mm (1.96”) | T9990050AL-4 | – | T9990050S | – | T9990050H | T9990050CT |

| 5St0aminmle (s1s. 9S6t”e)el | T9990050SS-4 | – | – | – | – | – |

| Part Number | Description | |||||

| T99923797 | Magnetic Anchor Clamp – holds actuator securely during tests on vertical surfaces | |||||

| T99912906 | Araldite Standard Two-Part Epoxy Adhesive, 2 x 15ml Tubes | |||||

| T99923147 | Dolly Cleaning Heating Tongs – EUR 220V / UK 240V | |||||

| T99923103 | Dolly Cleaning Heating Tongs – US 110V (No Plug) | |||||

| ● Calibration Certificate supplied as standard. | 1 | Including Actuator with Standard Skirt fitted. | ||||

| † | ||||||

| 50mm (2”) dollies are supplied in packs of 4. | ||||||

Automatic adhesion tester with selectable pull rates for 10, 14.2, 20 & 50mm diameter dollies. |

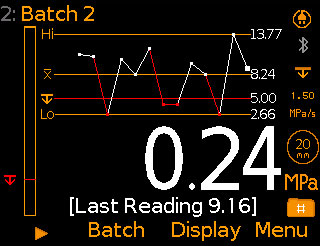

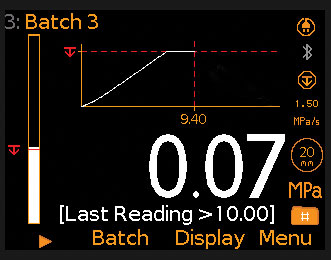

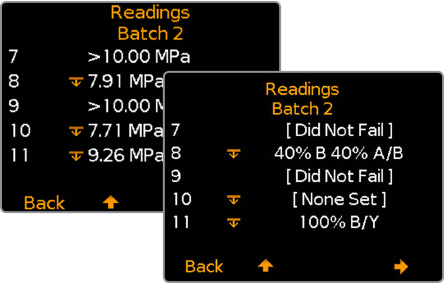

View trend graphs or live statistics alongside the reading value. |

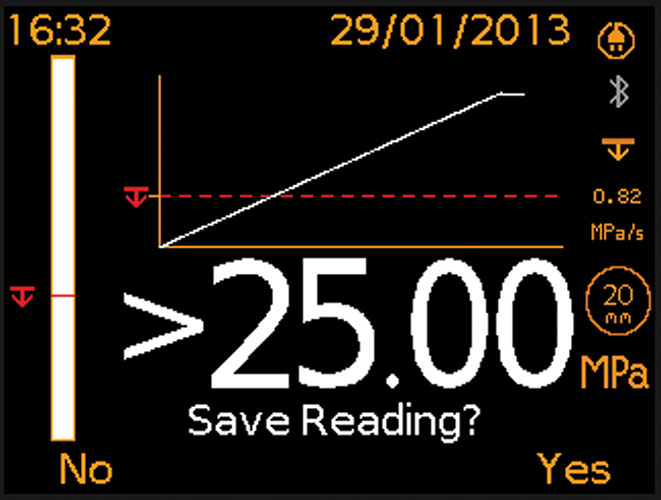

Individual user definable pull rate graphs can be saved with each reading. |

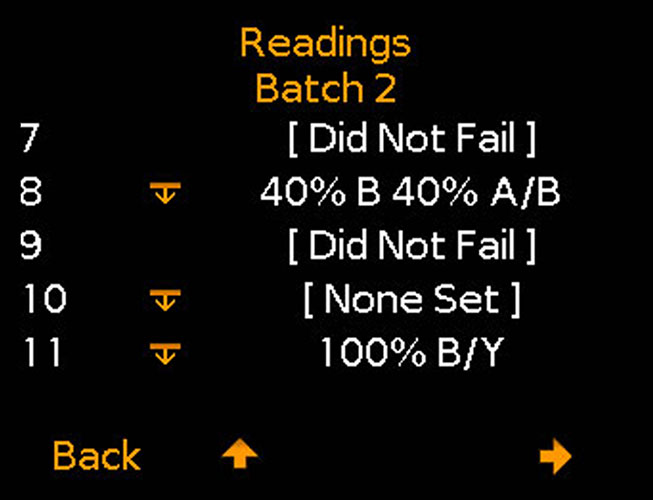

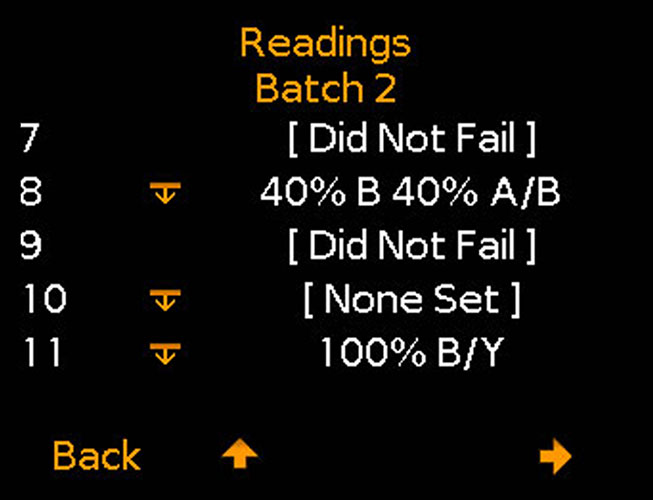

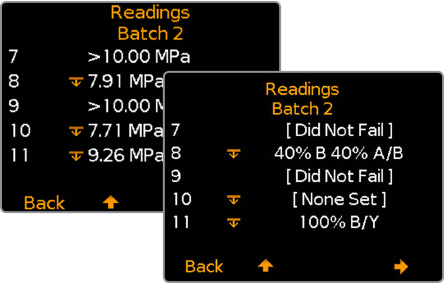

Stores individual readings and pull rate graphs in up to 2,500 alpha numeric batches, together with date, time and attribute information. |

Either pull to maximum or pull to preset limit. Unique time hold feature allows users to set a delay before pressure returns to zero. |

Save cohesive and adhesive failure attributes alongside your adhesion pull data in accordance with National and International Standards. |

Powered by either standard rechargeable batteries or AC mains*. Each battery charge performs up to 200 pulls. Battery recharge time less than 300 minutes. |

Transfer data to your PC via USB or Bluetooth® for further analysis with ElcoMaster™ software or view live pull rate graphs in ElcoMaster™ during the test. |

Using wireless Bluetooth® communication link the gauge to an Android™ or iPhoneǂ mobile device. Live GPS coordinates from your mobile device can be added to reports and emailed instantly. |

A range of standard and thin substrate actuator skirts allow each gauge to be use with 10, 14.2, 20 or 50mm diameter reusable dollies, ideal for testing coatings on thick, thin, flat, or convex substrates. |

The optional magnetic anchor clamp ensures the actuator doesn’t fall during tests on vertical surfaces or testing at height. |

Supplied in a robust plastic carry case for easy transportation to and around the job site. |

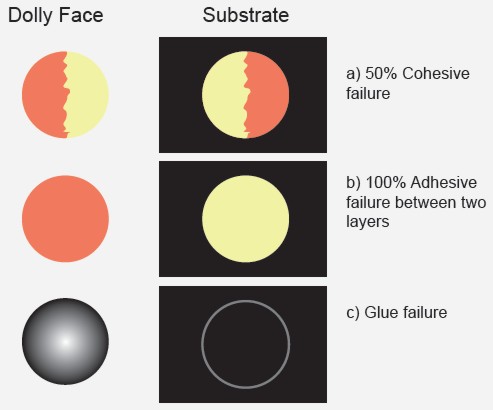

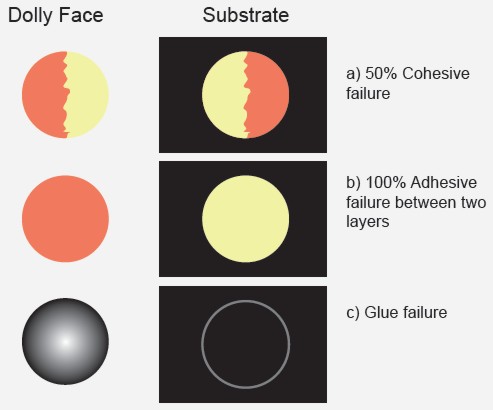

Assessing The Results – Failure Attributes

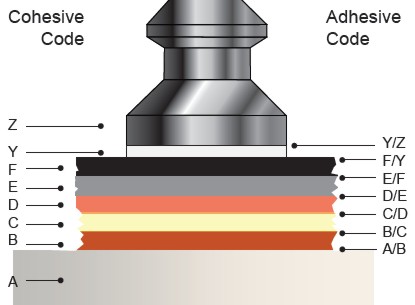

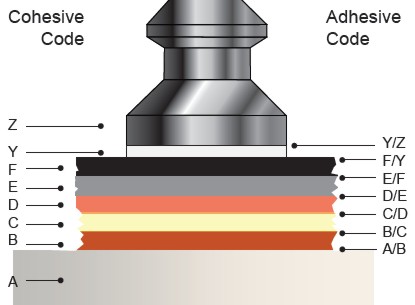

Many National and International Standards, including ISO 4624 & ASTM D4541, require the user to record not only the pull-off force but also the nature of the failure. This is done by examining the bottom of the dolly and assessing the failure. In ‘Advanced’ mode on the Elcometer 510 it is possible to select the ‘Attributes’ feature (Menu/Setup/Gauge Mode/Advanced) allowing the nature of the fracture to be recorded against each reading and stored within the batch

Examining The Dolly

510 dolly surface image

a) Cohesive Failure: The coating fails within the body of a coating layer leaving the same coating on the surface and on the dolly face.

b) Adhesive Failure: Failure occurs at the interface between layers (intercoat) where one pulls away from the other. The “coating” on the dolly face will not be the same as that on the test area.

c) Glue Failure: When no coating is present on the dolly it must be recorded as a failure of the glue. This may be due to incorrect or insufficient mixing of the component parts of the adhesive, incompatibility between the adhesive/coating/dolly/test surface.

The data is saved in the batch and can be viewed at any time displayed as

The data is saved in the batch and can be viewed at any time displayed as

##.## MPae N% A M% A/B, where;

##.## MPae = Pull Force in MPa or other measurement units (psi, Newtons or Nmm-2)

N% = Cohesive failure percentage

A = Cohesive failure layer

M% = Adhesion failure percentage

A/B = Intercoat adhesive failure layers

The data is saved in the batch and can be viewed at any time displayed as

##.## MPae N% A M% A/B, where;

##.## MPae = Pull Force in MPa or other measurement units (psi, Newtons or Nmm-2)

N% = Cohesive failure percentagef

A = Cohesive failure layer

M% = Adhesion failure percentagef

A/B = Intercoat adhesive failure layers

d The number of layers can be user-defined for each batch via Batch/New Batch/Number of Layers. This will affect the number of layers available for selection during attribute recording. The maximum number of layers available is five, excluding the substrate and glue.

e Or equivalent units.

f To the nearest 10%, in line with International Standards.

Can be used in accordance with:

ASTM C1583, ASTM D4541, ASTM D7234-12, AS/NZS 1580.408.5, BS 1881-207, DIN 1048-2, EN 1015-12, EN 12636, EN 13144, EN 1348, EN 1542, EN 24624, ISO 16276-1, ISO 4624, NF T30-606, NF T30-062

![]() New PDF User Manual: Adhesion testers on concrete

New PDF User Manual: Adhesion testers on concrete

Non-destructively measure the strength of the bond between the coating and the substrate

Elcometer 500 features state-of-the-art electronics that accurately, repeatably and reliably measures up to 9mm (355mils) coatings on concrete, or other similar surfaces.

Hand-held, waterproof, ruggedly designed, it has intuitive menu in multiple languages, ideal for the laboratory or field use. Test with confidence on flat or curved surfaces using the following simple procedure: Glue dollies to the coating and once it has cured, use the adhesion tester to pull the coating off the surface to assess adhesion.

Elcometer 510 is similar in operation to the Elcometer 506 except it is operated automatically and not manually.

Understanding Pull-off adhesion testing – Elcometer 510 and other devices

When testing coatings on low bond strength substrates such as concrete, wood or other fibrous materials, a larger surface area of dolly (50mm) is required to provide accurate, repeatable and reproducible results.

Using the smaller area dolly (10mm) on tiny parts or curved surfaces ensures accurate and consistent results.

Elcometer 510

- The automatic hydraulic pump ensures smooth and continuous pressure application for consistent, repeatable results

- Set adjustable pull rates @ 0.04, 0.08, 0.12, 0.16, 0.20 MPa/s(5, 8, 16, 24, 30psi/s)

- Can be used with 10, 14.2, 20 and 50mm diameter dollies

- User-definable limits with unique pressure hold and release function

- User-definable measurement range with an accuracy of ±1% of full scale:

- 10mm dolly: 14400psi (100MPa)

- 14.2mm dolly: 7200psi (50MPa)

- 20mm dolly: 3600psi (25 MPa)

- 50mm dolly: 580psi (4MPa)

- Dust and water-resistant rugged design to IP64

- Interchangeable units: MPa, psi, Nmm2 and N

- A range of standard and thin substrate actuator skirts (compatible with Elcometer 506) available for testing coatings on thick, thin, flat or convex substrates

- Store up to 60 readings

- USB and Bluetooth® data output – Compatible with ElcoMaster™ App for iPhone, iPod, iPad and Android mobile devices

Pull-off adhesion tester specifications

| Adhesion | ||||

| Product Features | ■ Standard | □ Optional | ||

| Model S | Model T | |||

| Repeatable & reproducible measurements | ■ | ■ | ||

| Easy to use menu structure; in multiple languages | ■ | ■ | ||

| Tough, impact, waterproof & dust resistant; equivalent to IP64 | ■ | ■ | ||

| Bright LCD colour screen; with ambient light sensor | ■ | ■ | ||

| Scratch & solvent resistant display; 2.4” (6cm) TFT | ■ | ■ | ||

| Calibration certificate | ■ | ■ | ||

| 2 year gauge warranty | ■ | ■ | ||

| Automatic rotating display; 0°, 180° | ■ | ■ | ||

| Data output via USB (Live readings – and batch) | ■ | ■ | ||

| Data output via Bluetooth ® | ■ | |||

| PC command; start & stop gauge from a PC with live readings (USB only) | ■ | |||

| Switchable Units (MPa, psi, N, N/mm -2) | ■ | ■ | ||

| On-Screen Statistics (η, x-, σ, hi, lo, COV, N>hi limit ǂ) | ■ | ■ | ||

| Pull Rate Indicator | ■ | ■ | ||

| Trend Graph | ■ | ■ | ||

| Pull Rate Graph (Load v Time) | ■ | |||

| Interchangeable Dolly Selection; 10, 14.2, 20 & 50mm | ■ | ■ | ||

| User Selectable Pull Rates; (Model S & Model T Standard Mode) 10mm: 1.00, 2.00, 3.00, 4.00, 5.00 MPa/s 125, 200, 400, 600, 725psi/s 14.2mm: 0.4, 0.7, 1.4, 2.0, 2.5 MPa/s 60, 100, 200, 300, 360psi/s 20mm: 0.2, 0.3, 0.7, 1.0, 1.2 MPa/s 30, 50, 100, 150, 180psi/s 50mm: 0.04, 0.08, 0.12, 0.16, 0.20 MPa/s 5, 8, 16, 24, 30psi/s |

■ | ■ | ||

| User Selectable Pull Rates; (Model T Advanced Mode) | ||||

| 10mm: 0.40 – 5.60 MPa/s | 58 – 812psi/s | in 0.1MPa / 1psi steps | ||

| 14.2mm: 0.20 – 2.80 MPa/s | 29 – 403psi/s | in 0.1MPa / 1psi steps | ■ | |

| 20mm: 0.10 – 1.40 MPa/s | 15 – 203psi/s | in 0.1MPa / 1psi steps | ||

| 50mm: 0.02 – 0.22 MPa/s | 2 – 32psi/s | in 0.01MPa / 0.1psi steps | ||

| User Selectable Limit & Limit Hold Time | ■ | |||

| Gauge Memory; maximum number of readings | 60 | 60,000* | ||

| Number of Batches (Alpha Numeric – Model T) | 1 | 2,500 | ||

| Attribute Modes to meet National & International Standards | ■ | |||

| Display Modes | ||||

| Readings, Selected Stats & Run Chart (last 20 readings) | ■ | ■ | ||

| Pull Rate Graphs | ■ | |||

| Batch Review | ■ | |||

| Power; Battery (B), AC Mains Power (M) | B | B, M | ||

| USB Cable & ElcoMasterTM 2.0 CD | ■ | ■ | ||

| Power Cable with Multi International Plug Adaptor (UK, EU, US, AUS) | ■ | |||

| Plastic Transit Case | ■ | ■ | ||

| Date & Time | ■ | |||

| In Field Adhesion Calibration Verification Mode | ■ | ■ | ||

| ǂModel T only. | ||||

| * When ‘Rate Graph’ is enabled, the number of readings that can be stored depends on the graph resolution selected | ||||

| Part Number | Description | Certificate | ||||

| F510-20S | Elcometer 510 Model S Automatic Adhesion Gauge; 20mm Kit | ● | ||||

| F510-20T | Elcometer 510 Model T Automatic Adhesion Gauge; 20mm Kit | ● | ||||

| F510-50S | Elcometer 510 Model S Automatic Adhesion Gauge; 50mm Concrete Kit | ● | ||||

| F510-50T | Elcometer 510 Model T Automatic Adhesion Gauge; 50mm Concrete Kit | ● | ||||

| Pressure Accuracy | ±1% of full scale | Pull Rate Accuracy | ±(2.5% + 0.3 seconds) | |||

| Pressure Resolution | 0.01MPa (1 psi) | Pull Rate Resolution | 0.01MPa/s (1psi/s) | |||

| Dolly Diameter | 10mm (0.39”) | 14.2mm (0.56”) | 20mm (0.76”) | 50mm (1.96”) | ||

| Operating Range | 8 to 100 MPa (1200 to 14400 psi) |

4 to 50 MPa (600 to 7200 psi) |

2 to 25 MPa (300 to 3600 psi) |

0.3 to 4 MPa (50 to 580 psi) |

||

| Pull Rate Range | 0.4 – 5.6MPa/s (58 – 812psi/s) |

0.2 – 2.8MPa/s (29 – 403psi/s) |

0.1 – 1.4MPa/s (15 – 203psi/s) |

0.02 – 0.22MPa/s (2 – 32psi/s) |

||

| Gauge Dimensions | 260 x 100 x 66mm (6.3 x 3.9 x 2.6”) | |||||

| Actuator Height1 | 85mm (3.4”) | 85mm (3.4”) | 85mm (3.4”) | 110mm (4.3”) | ||

| Instrument Weight1 | 2.9kg (6.4lb) | 2.9kg (6.4lb) | 2.9kg (6.4lb) | 3.1kg (8.3lb) | ||

| Kit Weight | – | – | 6.1kg (13.5lb) | 7.3kg (16.1lb) | ||

| Power Supply | 8 x AA NiMH/Alkaline batteries (16 rechargeable batteries supplied complete with charger) or AC mains power (Model T only) |

|||||

| Battery Life | ~200 pulls per charge up to 25MPa (3600psi) at 1MPa/s (150psi/s), recharge time <5 hours | |||||

| Packing List: | Elcometer 510 Adhesion Tester with 20mm dollies (x10), standard skirt for 20mm dollies, 20mm dolly | |||||

| 20mm Kit | cutter handle, 20mm dolly cutter, Araldite standard two part epoxy adhesive (2 x 15ml tubes), abrasive | |||||

| pad, shoulder harness, carry case, 16 x AA MiMH rechargeable batteries & charger (UK, EU, US, AUS), | ||||||

| mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster TM CD & USB cable, calibration certificate | ||||||

| and operating instructions. | ||||||

| Packing List: | Elcometer 510 Adhesion Tester with 50mm dollies (x6), standard skirt for 50mm dollies, 50mm dolly | |||||

| 50mm Kit | cutter arbor, 50mm dolly cutter, Araldite standard two-part epoxy adhesive (2 x 15ml tubes), abrasive | |||||

| pad, shoulder harness, carry case, 16 x AA MiMH rechargeable batteries & charger (UK, EU, US, AUS), | ||||||

| mains power supply (UK, EU, US, AUS) (Model T), ElcoMaster TM CD & USB cable, calibration certificate | ||||||

| and operating instructions. | ||||||

| Accessories | ||||||

| Dolly Diameter | Pack of 10† | Pack of 100 | Standard Skirt | Thin Substrate Skirt | ACrubttoerr Handle/ | Dolly Cutter |

| 10mm (0.39”) | T5100010AL-10 | T5100010AL-100 | T9991420S | – | – | – |

| 14.2mm (0.56”) | T9990014AL-10 | T9990014AL-100 | T9991420S | T9990014T | T9991420H | T9990014CT |

| 20mm (0.76”) | T9990020AL-10 | T9990020AL-100 | T9991420S | T9990020T | T9991420H | T9990020CT |

| 50mm (1.96”) | T9990050AL-4 | – | T9990050S | – | T9990050H | T9990050CT |

| 5St0aminmle (s1s. 9S6t”e)el | T9990050SS-4 | – | – | – | – | – |

| Part Number | Description | |||||

| T99923797 | Magnetic Anchor Clamp – holds actuator securely during tests on vertical surfaces | |||||

| T99912906 | Araldite Standard Two-Part Epoxy Adhesive, 2 x 15ml Tubes | |||||

| T99923147 | Dolly Cleaning Heating Tongs – EUR 220V / UK 240V | |||||

| T99923103 | Dolly Cleaning Heating Tongs – US 110V (No Plug) | |||||

| ● Calibration Certificate supplied as standard. | 1 | Including Actuator with Standard Skirt fitted. | ||||

| † | ||||||

| 50mm (2”) dollies are supplied in packs of 4. | ||||||

Automatic adhesion tester with selectable pull rates for 10, 14.2, 20 & 50mm diameter dollies. |

View trend graphs or live statistics alongside the reading value. |

Individual user definable pull rate graphs can be saved with each reading. |

Stores individual readings and pull rate graphs in up to 2,500 alpha numeric batches, together with date, time and attribute information. |

Either pull to maximum or pull to preset limit. Unique time hold feature allows users to set a delay before pressure returns to zero. |

Save cohesive and adhesive failure attributes alongside your adhesion pull data in accordance with National and International Standards. |

Powered by either standard rechargeable batteries or AC mains*. Each battery charge performs up to 200 pulls. Battery recharge time less than 300 minutes. |

Transfer data to your PC via USB or Bluetooth® for further analysis with ElcoMaster™ software or view live pull rate graphs in ElcoMaster™ during the test. |

Using wireless Bluetooth® communication link the gauge to an Android™ or iPhoneǂ mobile device. Live GPS coordinates from your mobile device can be added to reports and emailed instantly. |

A range of standard and thin substrate actuator skirts allow each gauge to be use with 10, 14.2, 20 or 50mm diameter reusable dollies, ideal for testing coatings on thick, thin, flat, or convex substrates. |

The optional magnetic anchor clamp ensures the actuator doesn’t fall during tests on vertical surfaces or testing at height. |

Supplied in a robust plastic carry case for easy transportation to and around the job site. |

Assessing The Results – Failure Attributes

Many National and International Standards, including ISO 4624 & ASTM D4541, require the user to record not only the pull-off force but also the nature of the failure. This is done by examining the bottom of the dolly and assessing the failure. In ‘Advanced’ mode on the Elcometer 510 it is possible to select the ‘Attributes’ feature (Menu/Setup/Gauge Mode/Advanced) allowing the nature of the fracture to be recorded against each reading and stored within the batch

Examining The Dolly

510 dolly surface image

a) Cohesive Failure: The coating fails within the body of a coating layer leaving the same coating on the surface and on the dolly face.

b) Adhesive Failure: Failure occurs at the interface between layers (intercoat) where one pulls away from the other. The “coating” on the dolly face will not be the same as that on the test area.

c) Glue Failure: When no coating is present on the dolly it must be recorded as a failure of the glue. This may be due to incorrect or insufficient mixing of the component parts of the adhesive, incompatibility between the adhesive/coating/dolly/test surface.

The data is saved in the batch and can be viewed at any time displayed as

The data is saved in the batch and can be viewed at any time displayed as

##.## MPae N% A M% A/B, where;

##.## MPae = Pull Force in MPa or other measurement units (psi, Newtons or Nmm-2)

N% = Cohesive failure percentage

A = Cohesive failure layer

M% = Adhesion failure percentage

A/B = Intercoat adhesive failure layers

The data is saved in the batch and can be viewed at any time displayed as

##.## MPae N% A M% A/B, where;

##.## MPae = Pull Force in MPa or other measurement units (psi, Newtons or Nmm-2)

N% = Cohesive failure percentagef

A = Cohesive failure layer

M% = Adhesion failure percentagef

A/B = Intercoat adhesive failure layers

d The number of layers can be user-defined for each batch via Batch/New Batch/Number of Layers. This will affect the number of layers available for selection during attribute recording. The maximum number of layers available is five, excluding the substrate and glue.

e Or equivalent units.

f To the nearest 10%, in line with International Standards.

Can be used in accordance with:

ASTM C1583, ASTM D4541, ASTM D7234-12, AS/NZS 1580.408.5, BS 1881-207, DIN 1048-2, EN 1015-12, EN 12636, EN 13144, EN 1348, EN 1542, EN 24624, ISO 16276-1, ISO 4624, NF T30-606, NF T30-062

![]() New PDF User Manual: Adhesion testers on concrete

New PDF User Manual: Adhesion testers on concrete

0 items

0 items