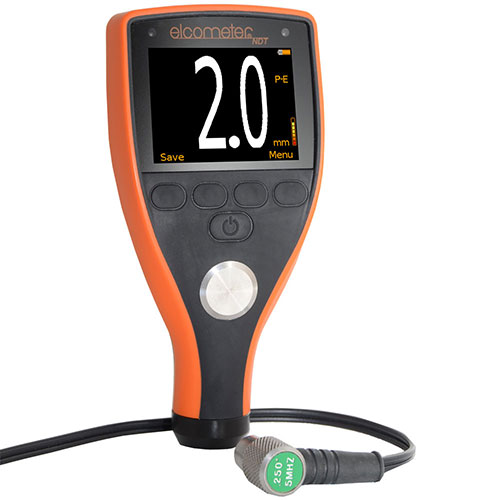

Ergonomic, rugged, accurate and easy to use, the Elcometer MTG & PTG range of ultrasonic Material and Precision thickness gauges is ideal for measuring and recording material thickness from just 0.15mm (0.006″) to 500mm (20″)

With automatic transducer recognition which ensures correct probe identification even when the Ultrasonic Material Thickness Gauge MTG2 is changed, a measurement rate of 4Hz (4 readings per second) and integral zero disc ensuring maximum accuracy of ±1%, the MTG2 is ideal for taking basic thickness measurements.

Factory calibrated for use on steel.

The MTG2 is supplied complete with 5MHz, ¼” transducer and is pre-calibrated for measuring on steel only with a thickness range of up to 500mm (20”) in Pulsed-Echo (P-E) mode.

Compatible with ElcoMaster™ software, individual readings can be downloaded via USB to PC or similar device for further analysis.

With a scratch and solvent resistant display, sealed, heavy duty and impact resistant design – dust and waterproof equivalent to IP54 – the MTG and PTG range is suitable for use in the harshest of environments.

The Elcometer NDT MTG range has a number of measurement modes available to help the user establish the most accurate thickness value. The modes available vary between models but normally increase as the model number increases.

SLASH YOUR COSTS BY GETTING A COMPLETE KIT:

LARGER PROJECTS INSPECTION KIT 5 | SEE OTHER KITS AVAILABLE

Key features

Pulsed – Echo Mode (P-E):

Ideal for pit and flaw detection, the total thickness from the base of the transducer to the material density boundary (typically the back-wall) is measured.

larger projects Inspection Kit 5

View Technical Specifications

Product Accessories

Dual & Single Element Transducers |

||||||||||||||||||||||

| Connector Type | Suitable for Measuring | Suitable For | ||||||||||||||||||||

|

Part Number

|

Probe Diameter

|

Probe Configuration

|

Damping

|

ThruPaintTM

|

Potted Right Angle

|

Microdot

|

Cast Iron

|

Plastics

|

Thin Plastics

|

Fiberglass

|

Thin Fiberglass

|

Steel

|

Glass

|

Aluminium

|

Titanium

|

MTG2

|

MTG4

|

MTG6

|

MTG8

|

PTG6

|

PTG8

|

Calibration Certificate

|

1.00 MHz Dual Element Thickness Transducer |

||||||||||||||||||||||

| TXC1M00EP-2 | 1/2″ | Right Angle | S | • | • | • | • | • | • | • | • | • | ||||||||||

2.25 MHz Dual Element Thickness Transducer |

||||||||||||||||||||||

| TXC2M25CP-2 | 1/4″ | Right Angle | S | • | • | • | • | • | • | • | • | • | ||||||||||

| TXC2M25EP-2 | 1/2″ | Right Angle | S | • | • | • | • | • | • | • | • | |||||||||||

3.50 MHz Dual Element Thickness Transducer |

||||||||||||||||||||||

| TXC3M50EP-1 | 1/2″ | Right Angle | CT, HD | • | • | • | • | • | • | • | • | • | • | • | ||||||||

5.00 MHz Dual Element Thickness Transducer |

||||||||||||||||||||||

| TXC5M00BP-4 | 3/16″ | Right Angle | CT, HD | • | • | • | • | • | • | • | • | • | • | |||||||||

| TXC5M00CP-4 | 1/4″ | Right Angle | S | • | • | • | • | • | • | • | • | • | ||||||||||

| TXC5M00BP-6 | 1/4″ | Right Angle | CT, HD | • | • | • | • | • | • | • | • | • | • | |||||||||

| TXC5M00CP-8 | 1/4″ | High Temp | HD | • | • | • | • | • | • | • | • | • | ||||||||||

| TXC5M00EP-3 | 1/2″ | Right Angle | S | • | • | • | • | • | • | • | • | • | ||||||||||

| TXC5M00EP-4 | 1/2″ | Right Angle | CT, HD | • | • | • | • | • | • | • | • | • | • | |||||||||

7.50 MHz Dual Element Thickness Transducer |

||||||||||||||||||||||

| TXC7M50BP-3 | 3/16″ | Right Angle | CT, HD | • | • | • | • | • | • | • | • | • | • | • | ||||||||

| TXC7M50CP-4 | 1/4″ | Right Angle | S | • | • | • | • | • | • | • | • | • | • | |||||||||

| TXC7M50CP-5 | 1/4″ | Right Angle | CT, HD | • | • | • | • | • | • | • | • | • | • | • | ||||||||

10.0 MHz Dual Element Thickness Transducer |

||||||||||||||||||||||

| TXC10M0BP-1 | 3/16″ | Right Angle | S | • | • | • | • | • | • | • | • | |||||||||||

| TXC10M0CP-4 | 1/4″ | Right Angle | S | • | • | • | • | • | • | • | • | |||||||||||

15.0 MHz Single Element Transducer |

||||||||||||||||||||||

| TXC15M0CM | 1/4″ | Right Angle | S | • | • | • | • | • | • | • | • | |||||||||||

20.0 MHz Single Element Transducer |

||||||||||||||||||||||

| TXC20M0CM | 1/4″ | Right Angle | S | • | • | • | • | • | • | • | • | |||||||||||

Delay Lines |

||||||||||||||||||||||

| Each gauge is supplied with 9mm and 12mm acrylic delay lines suitable for measuring on steel, aluminum and titanium. If measuring on thin plastics using Plastic Mode (PLAS), a graphite delay line must be used. These are available to purchase as optional accessories. |

||||||||||||||||||||||

| Part Number | Description | |||||||||||||||||||||

| T92016528 | Acrylic Delay Line; 1/4 Dia x 9mm | |||||||||||||||||||||

| T92016529 | Acrylic Delay Line; 1/4 Dia x 12mm | |||||||||||||||||||||

| T92023853-4 | Graphite Delay Line; 1/4 Dia x 3/16″ | |||||||||||||||||||||

| All transducers are supplied with a calibration certificate HD—Highly damped Transducer CT—Damped Coating Thickness Transducer S—–Standard undamped Transducer |

||||||||||||||||||||||

Standards

Can be used in accordance with:

ASTM E797, EN 14127, EN15317

Ergonomic, rugged, accurate and easy to use, the Elcometer MTG & PTG range of ultrasonic Material and Precision thickness gauges is ideal for measuring and recording material thickness from just 0.15mm (0.006″) to 500mm (20″)

With automatic transducer recognition which ensures correct probe identification even when the Ultrasonic Material Thickness Gauge MTG2 is changed, a measurement rate of 4Hz (4 readings per second) and integral zero disc ensuring maximum accuracy of ±1%, the MTG2 is ideal for taking basic thickness measurements.

Factory calibrated for use on steel.

The MTG2 is supplied complete with 5MHz, ¼” transducer and is pre-calibrated for measuring on steel only with a thickness range of up to 500mm (20”) in Pulsed-Echo (P-E) mode.

Compatible with ElcoMaster™ software, individual readings can be downloaded via USB to PC or similar device for further analysis.

With a scratch and solvent resistant display, sealed, heavy duty and impact resistant design – dust and waterproof equivalent to IP54 – the MTG and PTG range is suitable for use in the harshest of environments.

The Elcometer NDT MTG range has a number of measurement modes available to help the user establish the most accurate thickness value. The modes available vary between models but normally increase as the model number increases.

SLASH YOUR COSTS BY GETTING A COMPLETE KIT:

LARGER PROJECTS INSPECTION KIT 5 | SEE OTHER KITS AVAILABLE

Key features

Pulsed – Echo Mode (P-E):

Ideal for pit and flaw detection, the total thickness from the base of the transducer to the material density boundary (typically the back-wall) is measured.

larger projects Inspection Kit 5

View Technical Specifications

Product Accessories

Dual & Single Element Transducers |

||||||||||||||||||||||

| Connector Type | Suitable for Measuring | Suitable For | ||||||||||||||||||||

|

Part Number

|

Probe Diameter

|

Probe Configuration

|

Damping

|

ThruPaintTM

|

Potted Right Angle

|

Microdot

|

Cast Iron

|

Plastics

|

Thin Plastics

|

Fiberglass

|

Thin Fiberglass

|

Steel

|

Glass

|

Aluminium

|

Titanium

|

MTG2

|

MTG4

|

MTG6

|

MTG8

|

PTG6

|

PTG8

|

Calibration Certificate

|

1.00 MHz Dual Element Thickness Transducer |

||||||||||||||||||||||

| TXC1M00EP-2 | 1/2″ | Right Angle | S | • | • | • | • | • | • | • | • | • | ||||||||||

2.25 MHz Dual Element Thickness Transducer |

||||||||||||||||||||||

| TXC2M25CP-2 | 1/4″ | Right Angle | S | • | • | • | • | • | • | • | • | • | ||||||||||

| TXC2M25EP-2 | 1/2″ | Right Angle | S | • | • | • | • | • | • | • | • | |||||||||||

3.50 MHz Dual Element Thickness Transducer |

||||||||||||||||||||||

| TXC3M50EP-1 | 1/2″ | Right Angle | CT, HD | • | • | • | • | • | • | • | • | • | • | • | ||||||||

5.00 MHz Dual Element Thickness Transducer |

||||||||||||||||||||||

| TXC5M00BP-4 | 3/16″ | Right Angle | CT, HD | • | • | • | • | • | • | • | • | • | • | |||||||||

| TXC5M00CP-4 | 1/4″ | Right Angle | S | • | • | • | • | • | • | • | • | • | ||||||||||

| TXC5M00BP-6 | 1/4″ | Right Angle | CT, HD | • | • | • | • | • | • | • | • | • | • | |||||||||

| TXC5M00CP-8 | 1/4″ | High Temp | HD | • | • | • | • | • | • | • | • | • | ||||||||||

| TXC5M00EP-3 | 1/2″ | Right Angle | S | • | • | • | • | • | • | • | • | • | ||||||||||

| TXC5M00EP-4 | 1/2″ | Right Angle | CT, HD | • | • | • | • | • | • | • | • | • | • | |||||||||

7.50 MHz Dual Element Thickness Transducer |

||||||||||||||||||||||

| TXC7M50BP-3 | 3/16″ | Right Angle | CT, HD | • | • | • | • | • | • | • | • | • | • | • | ||||||||

| TXC7M50CP-4 | 1/4″ | Right Angle | S | • | • | • | • | • | • | • | • | • | • | |||||||||

| TXC7M50CP-5 | 1/4″ | Right Angle | CT, HD | • | • | • | • | • | • | • | • | • | • | • | ||||||||

10.0 MHz Dual Element Thickness Transducer |

||||||||||||||||||||||

| TXC10M0BP-1 | 3/16″ | Right Angle | S | • | • | • | • | • | • | • | • | |||||||||||

| TXC10M0CP-4 | 1/4″ | Right Angle | S | • | • | • | • | • | • | • | • | |||||||||||

15.0 MHz Single Element Transducer |

||||||||||||||||||||||

| TXC15M0CM | 1/4″ | Right Angle | S | • | • | • | • | • | • | • | • | |||||||||||

20.0 MHz Single Element Transducer |

||||||||||||||||||||||

| TXC20M0CM | 1/4″ | Right Angle | S | • | • | • | • | • | • | • | • | |||||||||||

Delay Lines |

||||||||||||||||||||||

| Each gauge is supplied with 9mm and 12mm acrylic delay lines suitable for measuring on steel, aluminum and titanium. If measuring on thin plastics using Plastic Mode (PLAS), a graphite delay line must be used. These are available to purchase as optional accessories. |

||||||||||||||||||||||

| Part Number | Description | |||||||||||||||||||||

| T92016528 | Acrylic Delay Line; 1/4 Dia x 9mm | |||||||||||||||||||||

| T92016529 | Acrylic Delay Line; 1/4 Dia x 12mm | |||||||||||||||||||||

| T92023853-4 | Graphite Delay Line; 1/4 Dia x 3/16″ | |||||||||||||||||||||

| All transducers are supplied with a calibration certificate HD—Highly damped Transducer CT—Damped Coating Thickness Transducer S—–Standard undamped Transducer |

||||||||||||||||||||||

Standards

Can be used in accordance with:

ASTM E797, EN 14127, EN15317

0 items

0 items