Get scientifically exact estimations on practically any surface, ferrous or non-ferrous.

Dry film thickness (DFT) evaluates the expected life of a coating & determines if it has been applied correctly per standards.

Knowing the thickness of dry film is paramount

It gives key data with regards to the longevity of the substrate, the item’s readiness for service, its appearance, and guarantees consistency with a large number of International Standards. Quality parameters such as ISO 9000, ISO 17025, and Guide 25, necessitate that the instruments be appropriately controlled, logged, and calibrated. In 1947, prior to the appearance of consumer electronics, Elcometer introduced one of the world’s first non-aggressive coating thickness gauges, the Elcometer 101.

Overlooked feature: why is the gauge reading rate so important?

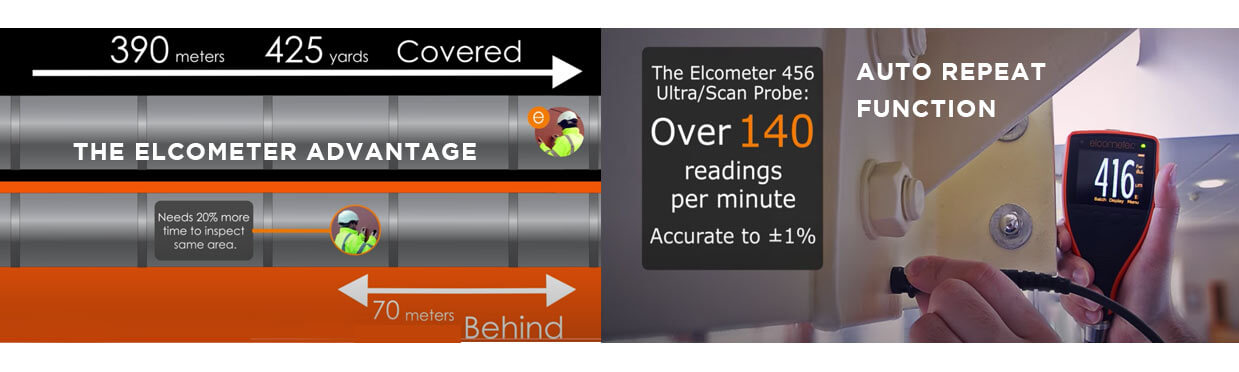

Saving time is one of the reasons why you would get Elcometer 456. Imagine two inspectors who are carrying out identical inspections of 3 spot measurements per 3 meters. One inspector is using the 456 that takes 70 readings per minute. The other inspector has a gauge that takes 50 readings per minute. That means he is almost 70m behind! It will take him another 2 minutes just to catch up, meaning he needs 20% longer to inspect the same area. So, by using a gauge that has a faster reading rate, the first inspector has saved himself one day in five.

How to save even more inspection time?

When the Auto Repeat function is selected, the probe can take 140+ accurate and reproducible readings every minute. Just slide the gauge along the surface and save both time and effort.

1 item

1 item