From the biggest infrastructure projects to our daily consumer gadgets, most manufactured surfaces feature anti-rust, decorative or other coatings. The smallest imperfection of this protective layer could trigger long-term problems and drive up repair costs. Preventing this damage using Elcometer adhesion testers will protect your investment in the long term.

1. CROSSHATCH TESTERS

You can get either Elcometer 107 or Elcometer 1542, where a cutter with 6 or 11 blades is used to cut two sets of lines at right angles. The debris is then removed using either adhesive tape, a brush, or compressed air, and the results determined by the use of tables. Elcometer 1542 Cross Hatch Adhesion Tester is ideal for measuring the cross hatch adhesion of coatings up to 60µm (2.4mils) on flat surfaces and test panels.

2. PUSH-OFF ADHESION TEST

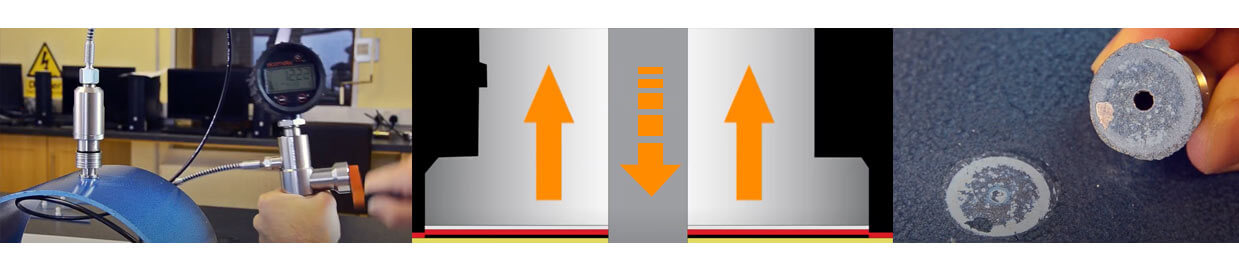

If you opt for Elcometer 108, you have a pin that goes through the center of a dolly that has been glued to the coated substrate, and pushes it off the coating, with the force recorded. There is a wide range of curved dollies available, each designed for a specific range of curvature. It is therefore ideal for convex and concave surface such as pipelines, tanks and other such objects.

3. PULL-OFF ADHESION METHOD

where a dolly is pulled off the coated substrate, and the resultant force is recorded.

All pull-off adhesion testers follow the same principle. A properly prepared dolly, or pull stub, is glued to the prepared coating, and, once the glue has fully cured, the dolly is pulled off – perpendicularly (or 90 degrees) from the surface. The resultant tensile pull-off force, together with the dolly diameter, and the conditions of the dolly, are all recorded.

Elcometer offers three different pull-off adhesion testers. You can get the original Elcometer 106, which is a hand-operated mechanical gauge, or the hydraulic Elcometer 506, with a separate, low-height actuator and a range of skirts for thick and thin substrates. Buying the Elcometer 510, which automatically applies the increasing force at a predefined and uniform rate, gets you the option of storing all of the results into memory by the simple press of a button.

Quality tests of the coating clearly indicate existing and/or potential damage, help identify weak areas of bondage between surfaces and their coating, or between layers of coating, or the consistency of bonding properties of some surfaces. Testing coated surfaces often is important in order to schedule check-up and repair routines, thus preventing the costly coating damage and its consequences.

Elcometer 510 adhesion tester makes sure that surface readiness and its coating are conforming to specified measurements.

Depending on your needs, you can get Elcometer 510 for flat or curved substrate application, Elcometer 107 for thin, thick, or tough coatings on all surfaces, and Elcometer 108, for coatings on tanks, pipelines, etc.

The longevity and ruggedness of Elcometer products and the consistency of its performance are matched by longevity and consistency of your coatings.

![]() New PDF User Manual: Elcometer adhesion tester on concrete

New PDF User Manual: Elcometer adhesion tester on concrete

View products available in this category

0 items

0 items