How to test wet and dry film thickness?

Excess coating negatively affects the longevity and the finish of the product

Too much of wet film can result in cracks when dry; too little film increases the risk of insufficient protection and rust spots. For powder coatings, the right thickness of applied powder is just as crucial: excessive powder means poor adhesion, and not enough – discoloration and less gloss.

One needs to measure the density of the powder using non-contact ultrasonic technology and provide a predictive value of the cured coat. A good example of this is the coating thickness gauge Elcometer 550.

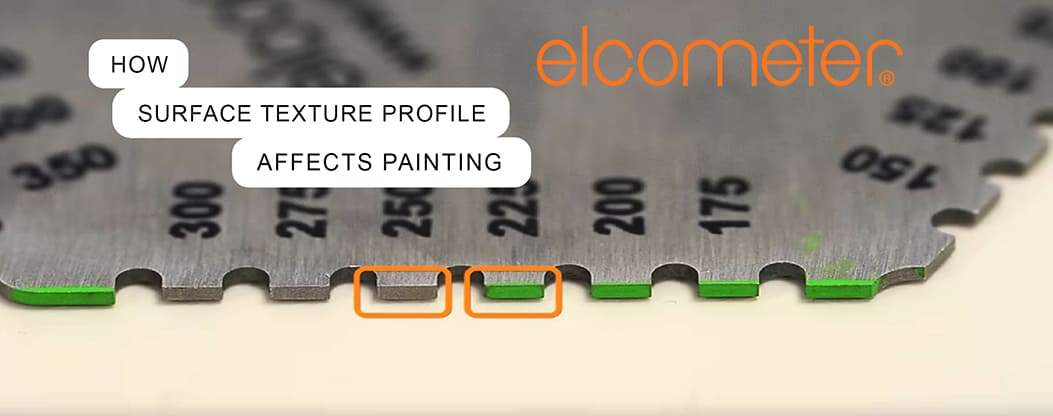

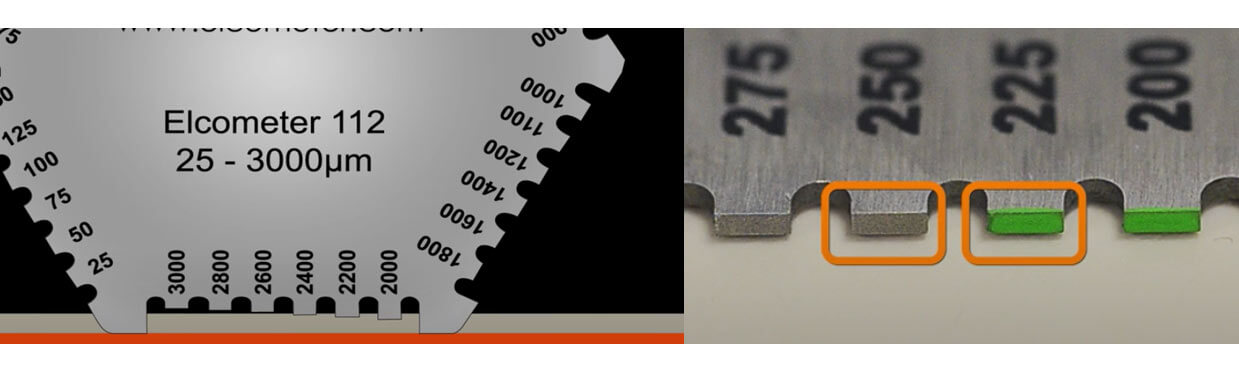

Wet Film Combs

To measure the wet film thickness, touch the substrate with the comb’s teeth at 90 90-degree angle and wait a few seconds. Remove the comb. The wet film thickness value is found between the biggest value, the ‘wet’ tooth and the smallest value ‘dry’ tooth.

You can test this instrument here: Aluminium Wet Film Comb | Long Edge Wet Film Comb

Wet Film thickness gauge (wheel)

By rolling the wheel on the wet freshly coated surface, we apply the wet coating to the extremities of the disk. A scale placed along this edge indicates the thickness. The scales exist in a variety of measurements from 0 to 25µm – 0 to 3000µm (0 to 1mil – 0 to 40mils). When the correlation of solids vs volume ratio is known (usually indicated in the manufacturer’s datasheet), the Elcometer Wet Film thickness gauge can predict the dry film thickness.

Test this: Elcometer 3230 – Imperial | Metric

Pfund Thickness Gauge

This gauge has two concentric cylinders one placed into another. A glass lens with measurements is placed within the central cylinder. When measuring, this spherical lens is pressed on the wet film. The mark is then measured and thickness indication is obtained using the supplied conversion table.

Take a look at this coating thickness gauge Elcometer 3233

0 items

0 items