Perform ultrasonic corrosion mapping with ease on projects big and small

Our full range of handheld corrosion thickness gauges lets you choose the right tool for the job. Offering a full range of measurement modes including Pulse-Echo Temp Comp Mode (PETP) and Coating Only Mode (CT) to Pulse-Echo Coating Mode (PECT). You can store up to 16,000 readings with individual waveforms in alphanumeric batches and full data logging through RS232 data output to Elcometer NDT data management software.

CG100 ABDL+ is ideal for all applications: it features automatic gain control (AGC) for ease of use or manual adjustment (-30dB to 70dB) to increase the amplitude of the received echo to suit the material properties, the .

The time corrected gain (TCG) feature automatically compensates for sound attenuation through a material, further increasing the performance of the gauge.

Built-in Gates allow users to set the measurement parameters either on or between waveforms, bypassing any surface echoes or noise from the material.

Threshold adjustment allows users to adjust the sensitivity of the gauge to detect signals with lower amplitudes.

The CG100ABDL+ thickness gauge stores up to 16,000 readings with individual waveforms in alphanumeric batches and full data logging through RS232 data output to Elcometer NDT data management software.

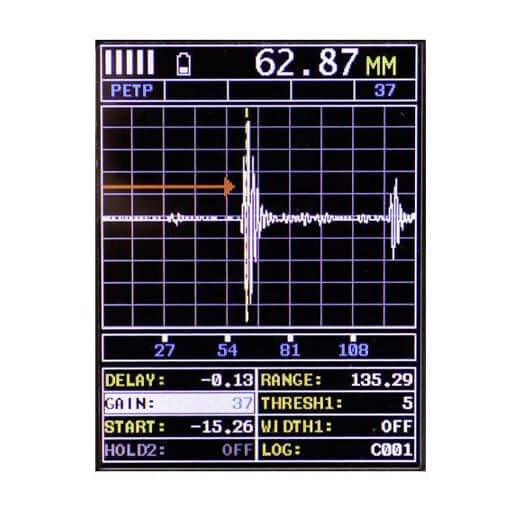

With its high contrasting color display, the CG100ABDL+ thickness gauge has a refresh rate of 120Hz providing users with an instant measurement response.

Advantages

- Range of display & measurement options: Pulse-Echo, Echo-Echo, Pulse-Echo Temp, Comp Mode (PETP), Coating Only Mode (CT), Pulse-Echo Coating Mode (PECT)

- Adjustable gain: -30dB to 70dB range

- Automatic gain control (AGC)

- Time corrected gain (TCG)

- Gate control

- Threshold adjustment

- 64 User-defined setups

- Multiple language display

- Multiple calibrations and material selection options

- High-speed scan mode: 32 readings per second

- Differential and minimal thickness alarm modes

- Data output and storage: 16,000 readings and waveforms or B-Scans

- Data management software

Specifications – ultrasonic corrosion mapping gauge

| Model & Part Number | CG100ABDL Corrosion Thickness Gauge |

| Material thickness digits display | – |

| B-Scan cross-sectional display | – |

| Combined B-Scan and digits display | – |

| Scan bar display | – |

| Coating thickness display | – |

| A-Scan Display | + Rectified, – Rectified, Full Waveform (RF) |

| Measurement Mode | PE, PETP (Temp Compensation), EE (ThruPaint™), EEV, CT (Coating) & PECT |

| Measurement Rate Manual: Scan mode Scan bar display |

4 readings per second 32 readings per second 6 readings per second |

| Measuring Range | PE: 0.63 – 508mm (0.025 – 19.999 inches) PETP: 0.63 – 508mm (0.025 – 19.999 inches) EE: 1.27 – 102mm (0.050 – 4.000 inches) EEV: 1.27 – 25.4mm (0.050 – 1.000 inch) CT: 12.7 – 254μm (0.0005 – 0.100 inch) PECT: 0.63 – 508mm (0.025 – 19.999 inches) PECT: 0.01 – 2.54mm (0.0005 – 0.100 inch) |

| Measurement Accuracy | ±0.01mm (±0.001 inch) |

| Measurement Resolution | 0.01mm (0.001 inch) |

| Velocity Calibration Range | 1250 – 9,999m/s (0.0492 – 0.3936in/ms) |

| Additional Features: High speed scan mode |

– |

| Differential mode | – |

| Limit alarm mode | – |

| B-Scan display speed | adjustable display speed |

| Flaw mode | Basic prove-up flaw detection using single element angle beam transducers |

| Calibration setups | 6 factory & 64 user-definable setups transferrable to and from a PC archive |

| Gates | 3 fully adjustable gates: start, stop, width & threshold |

| Damping | adjustable; impedance matching for optimizing transducer performance |

| Pulser type | dual 200-volt square wave pulses with adjustable pulse width (spike, thin, wide) and 50-volt cut/boost for greater penetration |

| Gain | manual, automatic gain control (AGC) with 110dB range (limited), time corrected gain (TCG) |

| Timing | precision 25MHz TCXO with a single shot 100MHz 8bit ultra-low-power 8-bit digitizer |

| Data logging | 8,000 with A/B-scan image & gauge settings 210,000 – coating, material, min, max thickness sequential and grid logging Alphanumeric batch identification OBSTRUCT indicates inaccessible locations |

| Calibration Options | single, two-point, velocity & material type |

| Transducer Probe Type | dual element & flaw prove up |

| Transducer Frequency Range | 1 – 10MHz |

| Transducer recognition | automatic & manual – selectable from a list |

| V-path / dual path error correction | automatic |

| Probe zero | automatic & manual (via integrated probe disk) |

| Display | 1/4 VGA AMOLED color display 57.6 x 43.2mm (2.27 x 1.78inch) viewable area |

| Display Refresh Rate | 120Hz |

| Units (selectable) | mm or inches |

| Backlight | adjustable brightness |

| Repeatability / Stability Indicator | – |

| Battery Type | 3 x AA alkaline |

| Battery Life (approximate) | 25 hours |

| Low Battery Indicator | – |

| Battery Save Mode | auto |

| Operating Temperature | -10 to 60ºC (14 to 140ºF) |

| Size (w x h x d) | 63.5 x 165.0 x 31.5mm (2.5 x 6.5 x 1.24 inches) |

| Weight (including batteries) | 383g (13.5oz) |

| Aluminum case design with the gasket-sealed end caps, waterproof membrane keypad |

– |

| Transducer Connector Type | LEMO |

| RS232 Interface | Bi-directional |

| Packing List | Elcometer NDT CG100ABDL+ gauge, couplant, carry case, user manual, test certificate, 3 x AA batteries, software, transfer cable |

Perform ultrasonic corrosion mapping with ease on projects big and small

Our full range of handheld corrosion thickness gauges lets you choose the right tool for the job. Offering a full range of measurement modes including Pulse-Echo Temp Comp Mode (PETP) and Coating Only Mode (CT) to Pulse-Echo Coating Mode (PECT). You can store up to 16,000 readings with individual waveforms in alphanumeric batches and full data logging through RS232 data output to Elcometer NDT data management software.

CG100 ABDL+ is ideal for all applications: it features automatic gain control (AGC) for ease of use or manual adjustment (-30dB to 70dB) to increase the amplitude of the received echo to suit the material properties, the .

The time corrected gain (TCG) feature automatically compensates for sound attenuation through a material, further increasing the performance of the gauge.

Built-in Gates allow users to set the measurement parameters either on or between waveforms, bypassing any surface echoes or noise from the material.

Threshold adjustment allows users to adjust the sensitivity of the gauge to detect signals with lower amplitudes.

The CG100ABDL+ thickness gauge stores up to 16,000 readings with individual waveforms in alphanumeric batches and full data logging through RS232 data output to Elcometer NDT data management software.

With its high contrasting color display, the CG100ABDL+ thickness gauge has a refresh rate of 120Hz providing users with an instant measurement response.

Advantages

- Range of display & measurement options: Pulse-Echo, Echo-Echo, Pulse-Echo Temp, Comp Mode (PETP), Coating Only Mode (CT), Pulse-Echo Coating Mode (PECT)

- Adjustable gain: -30dB to 70dB range

- Automatic gain control (AGC)

- Time corrected gain (TCG)

- Gate control

- Threshold adjustment

- 64 User-defined setups

- Multiple language display

- Multiple calibrations and material selection options

- High-speed scan mode: 32 readings per second

- Differential and minimal thickness alarm modes

- Data output and storage: 16,000 readings and waveforms or B-Scans

- Data management software

Specifications – ultrasonic corrosion mapping gauge

| Model & Part Number | CG100ABDL Corrosion Thickness Gauge |

| Material thickness digits display | – |

| B-Scan cross-sectional display | – |

| Combined B-Scan and digits display | – |

| Scan bar display | – |

| Coating thickness display | – |

| A-Scan Display | + Rectified, – Rectified, Full Waveform (RF) |

| Measurement Mode | PE, PETP (Temp Compensation), EE (ThruPaint™), EEV, CT (Coating) & PECT |

| Measurement Rate Manual: Scan mode Scan bar display |

4 readings per second 32 readings per second 6 readings per second |

| Measuring Range | PE: 0.63 – 508mm (0.025 – 19.999 inches) PETP: 0.63 – 508mm (0.025 – 19.999 inches) EE: 1.27 – 102mm (0.050 – 4.000 inches) EEV: 1.27 – 25.4mm (0.050 – 1.000 inch) CT: 12.7 – 254μm (0.0005 – 0.100 inch) PECT: 0.63 – 508mm (0.025 – 19.999 inches) PECT: 0.01 – 2.54mm (0.0005 – 0.100 inch) |

| Measurement Accuracy | ±0.01mm (±0.001 inch) |

| Measurement Resolution | 0.01mm (0.001 inch) |

| Velocity Calibration Range | 1250 – 9,999m/s (0.0492 – 0.3936in/ms) |

| Additional Features: High speed scan mode |

– |

| Differential mode | – |

| Limit alarm mode | – |

| B-Scan display speed | adjustable display speed |

| Flaw mode | Basic prove-up flaw detection using single element angle beam transducers |

| Calibration setups | 6 factory & 64 user-definable setups transferrable to and from a PC archive |

| Gates | 3 fully adjustable gates: start, stop, width & threshold |

| Damping | adjustable; impedance matching for optimizing transducer performance |

| Pulser type | dual 200-volt square wave pulses with adjustable pulse width (spike, thin, wide) and 50-volt cut/boost for greater penetration |

| Gain | manual, automatic gain control (AGC) with 110dB range (limited), time corrected gain (TCG) |

| Timing | precision 25MHz TCXO with a single shot 100MHz 8bit ultra-low-power 8-bit digitizer |

| Data logging | 8,000 with A/B-scan image & gauge settings 210,000 – coating, material, min, max thickness sequential and grid logging Alphanumeric batch identification OBSTRUCT indicates inaccessible locations |

| Calibration Options | single, two-point, velocity & material type |

| Transducer Probe Type | dual element & flaw prove up |

| Transducer Frequency Range | 1 – 10MHz |

| Transducer recognition | automatic & manual – selectable from a list |

| V-path / dual path error correction | automatic |

| Probe zero | automatic & manual (via integrated probe disk) |

| Display | 1/4 VGA AMOLED color display 57.6 x 43.2mm (2.27 x 1.78inch) viewable area |

| Display Refresh Rate | 120Hz |

| Units (selectable) | mm or inches |

| Backlight | adjustable brightness |

| Repeatability / Stability Indicator | – |

| Battery Type | 3 x AA alkaline |

| Battery Life (approximate) | 25 hours |

| Low Battery Indicator | – |

| Battery Save Mode | auto |

| Operating Temperature | -10 to 60ºC (14 to 140ºF) |

| Size (w x h x d) | 63.5 x 165.0 x 31.5mm (2.5 x 6.5 x 1.24 inches) |

| Weight (including batteries) | 383g (13.5oz) |

| Aluminum case design with the gasket-sealed end caps, waterproof membrane keypad |

– |

| Transducer Connector Type | LEMO |

| RS232 Interface | Bi-directional |

| Packing List | Elcometer NDT CG100ABDL+ gauge, couplant, carry case, user manual, test certificate, 3 x AA batteries, software, transfer cable |

0 items

0 items