Factory calibrated to 39 different materials. MTG4 TXC version comes with a transducer.

With a choice of calibration options and measurement modes, the MTG4 is ideal for taking readings on a wide range of coated and uncoated materials.

As well as all the features of the MTG2, the MTG4 has two calibration options. Using an uncoated sample of test material of a known thickness, the gauge can be calibrated using 1-Point calibration. Alternatively, the user can select one of 39 pre-set materials stored within the gauge including; aluminium, steel, stainless steel, cast iron, plexiglass, PVC, polystyrene and polyurethane.

Echo-Echo ThruPaintTM (E-E) measurement mode enables readings to be taken on coated materials with a thickness range up to 25.4mm (1”). In Echo-Echo ThruPaint™ mode, the coating thickness is ignored and the material thickness from the top surface of the material to the material density boundary is displayed.

Compatible with ElcoMaster™ software, individual readings can be downloaded via USB to PC or similar device for further analysis.

Pulsed – Echo Mode (P-E):

Ideal for pit and flaw detection, the total thickness from the base of the transducer to the material density boundary (typically the back-wall) is measured.

Echo – Echo ThruPaint™ Mode (E-E):

Also known as ThruPaint™ mode, the coating thickness is ignored and the material thickness from the top surface of the material to the material density boundary (typically the back-wall) is measured. To use Echo-Echo ThruPaint™ mode, a high damped, coating thickness transducer is required.

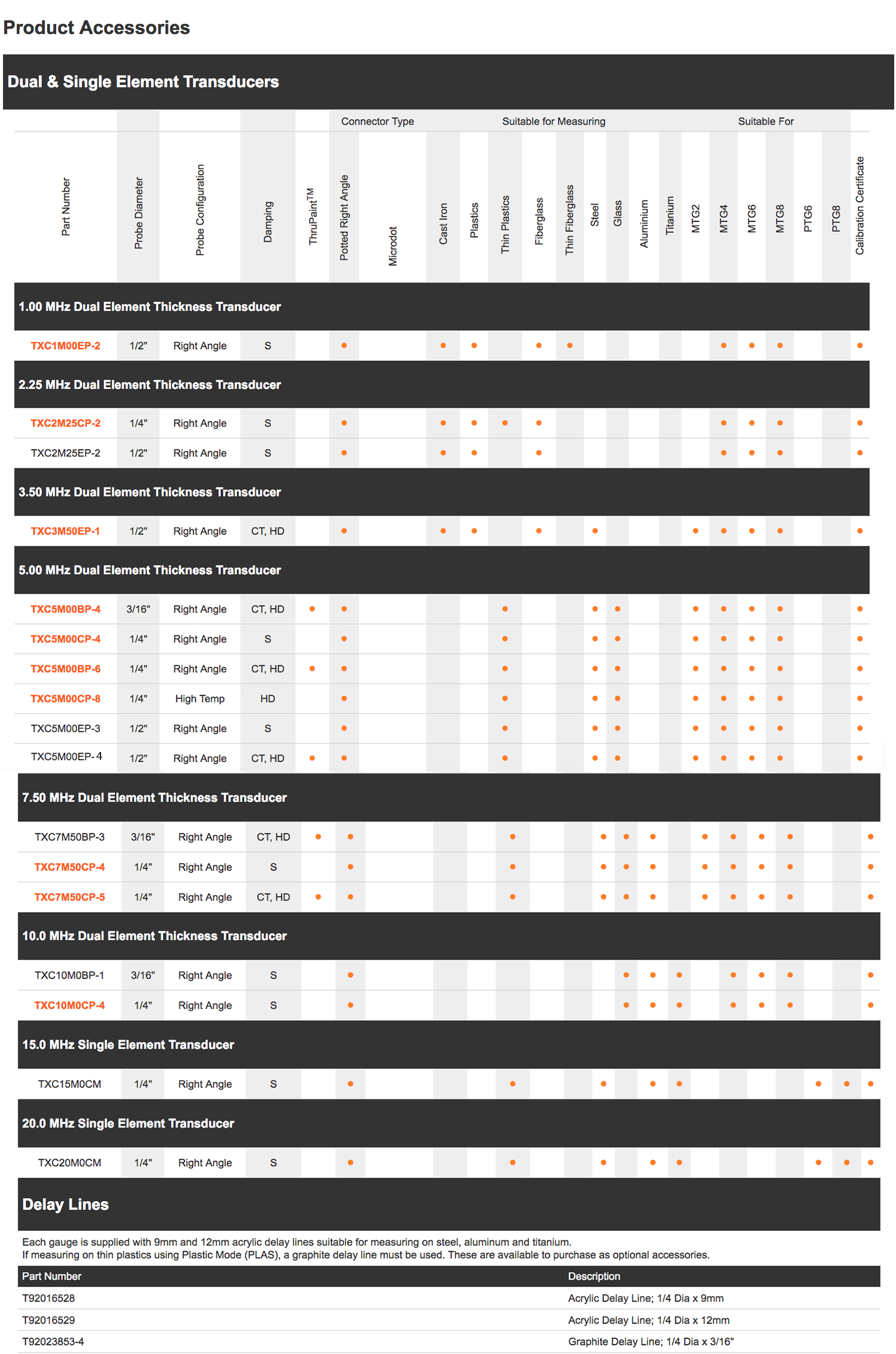

Delay Lines

Each gauge is supplied with 9mm and 12mm acrylic delay lines suitable for measuring on steel, aluminum and titanium.

If measuring on thin plastics using Plastic Mode (PLAS), a graphite delay line must be used. These are available to purchase as optional accessories.Part NumberDescriptionT92016528Acrylic Delay Line; 1/4 Dia x 9mmT92016529Acrylic Delay Line; 1/4 Dia x 12mmT92023853-4Graphite Delay Line; 1/4 Dia x 3/16″All transducers are supplied with a calibration certificate

HD—Highly damped Transducer

CT—Damped Coating Thickness Transducer

S—–Standard undamped Transducer

STANDARDS MTG: ASTM E797, EN 14127, EN15317STANDARDS PTG: EN14127, EN15317

Factory calibrated to 39 different materials. MTG4 TXC version comes with a transducer.

With a choice of calibration options and measurement modes, the MTG4 is ideal for taking readings on a wide range of coated and uncoated materials.

As well as all the features of the MTG2, the MTG4 has two calibration options. Using an uncoated sample of test material of a known thickness, the gauge can be calibrated using 1-Point calibration. Alternatively, the user can select one of 39 pre-set materials stored within the gauge including; aluminium, steel, stainless steel, cast iron, plexiglass, PVC, polystyrene and polyurethane.

Echo-Echo ThruPaintTM (E-E) measurement mode enables readings to be taken on coated materials with a thickness range up to 25.4mm (1”). In Echo-Echo ThruPaint™ mode, the coating thickness is ignored and the material thickness from the top surface of the material to the material density boundary is displayed.

Compatible with ElcoMaster™ software, individual readings can be downloaded via USB to PC or similar device for further analysis.

Pulsed – Echo Mode (P-E):

Ideal for pit and flaw detection, the total thickness from the base of the transducer to the material density boundary (typically the back-wall) is measured.

Echo – Echo ThruPaint™ Mode (E-E):

Also known as ThruPaint™ mode, the coating thickness is ignored and the material thickness from the top surface of the material to the material density boundary (typically the back-wall) is measured. To use Echo-Echo ThruPaint™ mode, a high damped, coating thickness transducer is required.

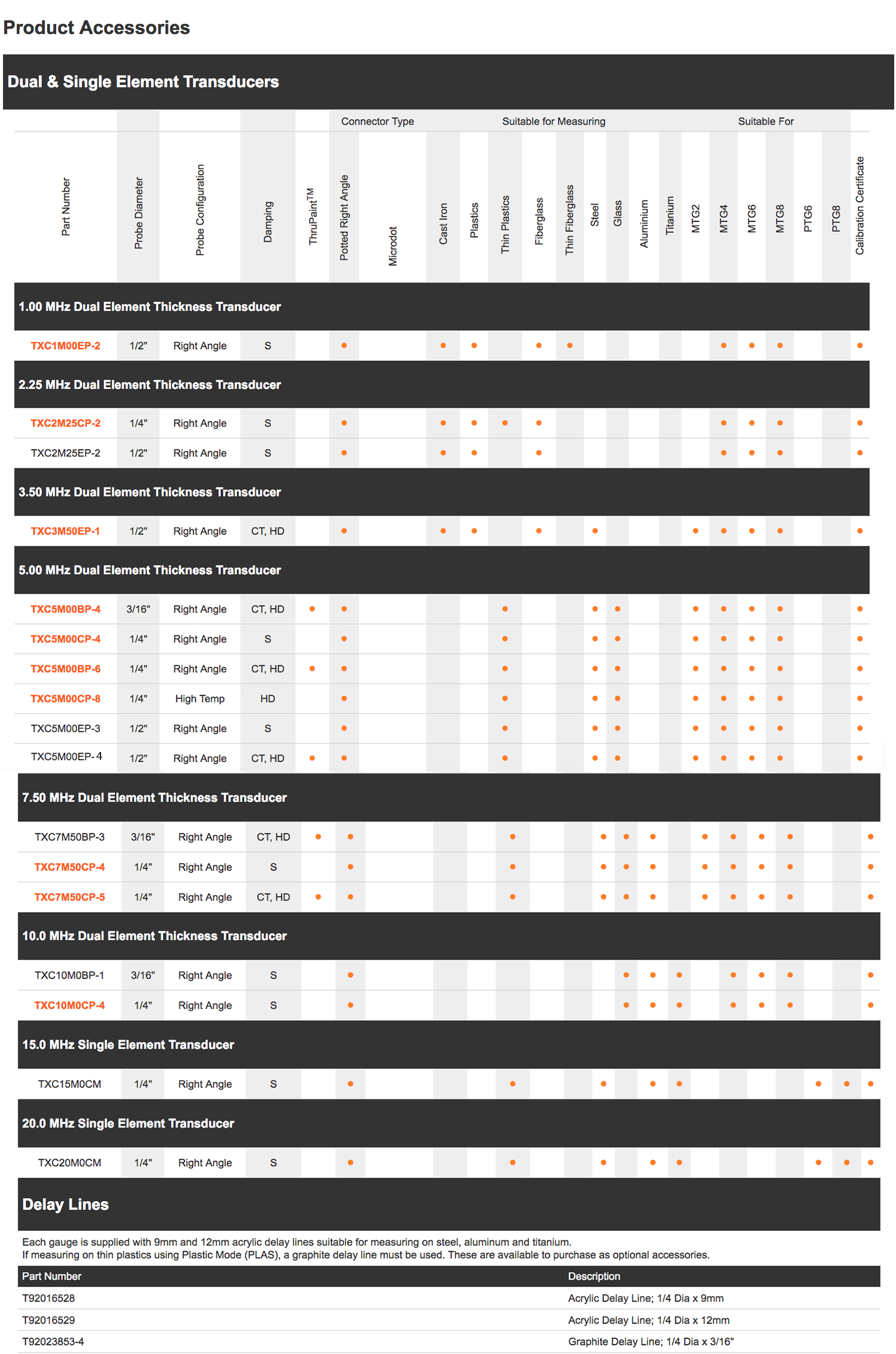

Delay Lines

Each gauge is supplied with 9mm and 12mm acrylic delay lines suitable for measuring on steel, aluminum and titanium.

If measuring on thin plastics using Plastic Mode (PLAS), a graphite delay line must be used. These are available to purchase as optional accessories.Part NumberDescriptionT92016528Acrylic Delay Line; 1/4 Dia x 9mmT92016529Acrylic Delay Line; 1/4 Dia x 12mmT92023853-4Graphite Delay Line; 1/4 Dia x 3/16″All transducers are supplied with a calibration certificate

HD—Highly damped Transducer

CT—Damped Coating Thickness Transducer

S—–Standard undamped Transducer

STANDARDS MTG: ASTM E797, EN 14127, EN15317STANDARDS PTG: EN14127, EN15317

0 items

0 items