Monitor the integrity of the protective coating throughout its service life.

What makes Elcometer 270 so efficient?

- Ready to use

- Automatic sensitivity calibration and voltage checks

- Low battery indicator

- Visual/audible alarms

- Integral and separate wand functionality

- A wide range of fully interchangeable wand accessories

- Three model variants – single, dual, or triple voltages

- Easy-release snag-proof cables

- Large standard sponge

- An inspection kit for all your requirements is available

Pinhole Detector – Elcometer 270/3 Add to cart

Pinhole Detector – Elcometer 270/4 Add to cart

Pinhole Detectors Inspector’s Kit Add to cart

Pinhole & Porosity Detection

Premature corrosion of a substrate is usually due to the failure of the coating. A major cause of failure is the presence of flaws in the finished coating. Collectively referred to as a coating’s porosity the main types of flaw are described below:

Runs & Sags:

The wet coating moves under gravity leaving a thin dry film.

Cissing:

Occurs when a coating does not re-flow to cover the voids generated by air bubbles being released from the surface of a coating.

Cratering:

Occurs when the substrate is wet or if the coating has poor flow characteristics, thus creating voids in the coating.

Pinholes:

Caused either by air entrapment which is then released from the surface, or by the entrapment of particulates (dust, sand, etc.) that do not stay in place.

Over Coating:

If too much coating is applied to a substrate, as the coating cures it can crack from internal stresses of the coating. Under Coating:

Areas are not coated, or the coating flows away from particular edges, corners of a substrate and welds.

Furthermore over a rough surface profile, insufficient coating may leave the profile’s peaks exposed.

Testing for pînholes with the wet sponge method

Pinholes are caused by air entrapment, which is then released from the surface, or by the entrapment of particulates (dust, sand etc.) that do not stay in place. The Elcometer 270 range utilizes the wet sponge technique and has been designed to set a new standard for wet sponge pinhole detectors – a high-quality, low-voltage detector with similar accessories to a high-voltage spark tester. They are available both as an individual gauge and as pinhole inspection kit. Elcometer also offers the 260 UV Pinhole Flashlight for a quick, low-cost method of testing coatings for pinholes.

Pinholes are caused by air entrapment, which is then released from the surface, or by the entrapment of particulates (dust, sand etc.) that do not stay in place. The Elcometer 270 range utilizes the wet sponge technique and has been designed to set a new standard for wet sponge pinhole detectors – a high-quality, low-voltage detector with similar accessories to a high-voltage spark tester. They are available both as an individual gauge and as pinhole inspection kit. Elcometer also offers the 260 UV Pinhole Flashlight for a quick, low-cost method of testing coatings for pinholes.

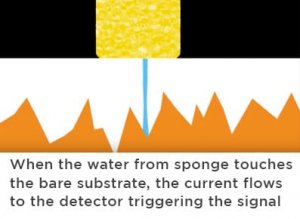

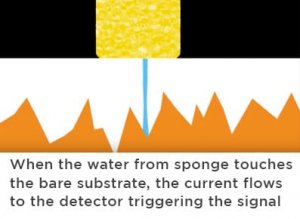

A low voltage is applied to a moist sponge. When the sponge moves over a coating flaw, liquid penetrates to the substrate and completes an electrical circuit, setting off the alarm. The wet sponge technique is suitable for measuring insulated coatings less than 500 µm or 20 mil on conductive substrates and is ideal for powder coatings and other coatings where the user does not wish to damage the coating.

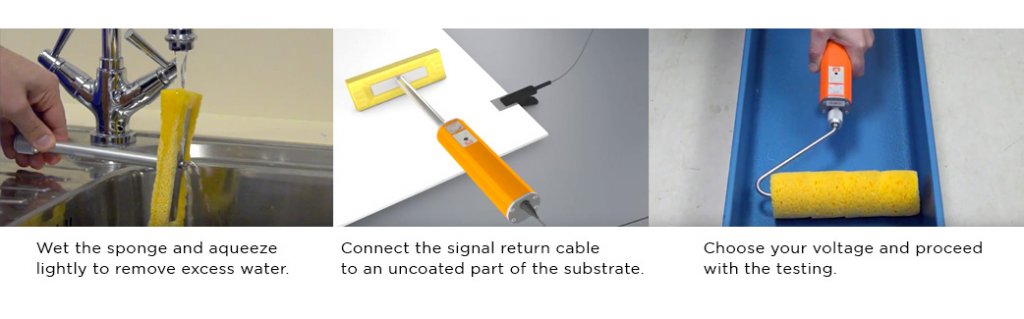

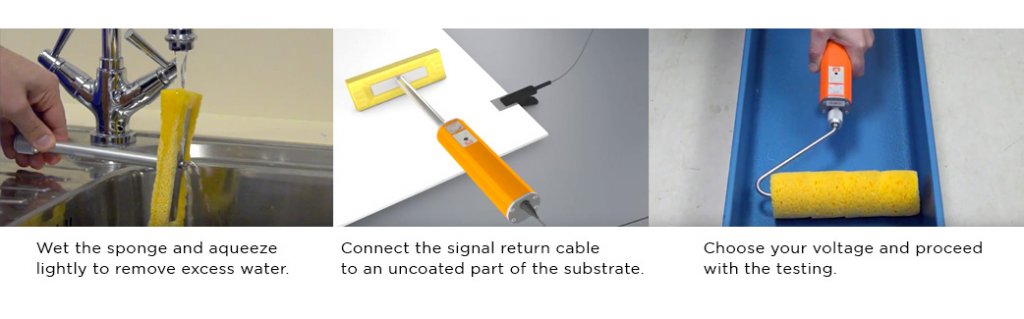

how to use Elcometer 270:

| Model | Elcometer 270/4 Pinhole Detector | |

| Voltage | 9V, 67.5V, and 90V | |

| Maximum Measurement Range | 500µm (20mils) | |

| Sensitivity | 9V: 90kΩ ±5% 67.5V: 125kΩ ±5% 90V: 400kΩ ±5% |

|

| Battery Life (continuous use) | 9V: up to 200 hours 67.5V: up to 100 hours 90V: up to 80 hours |

|

| Battery Type | 3 x AA (LR1600) 1.5V alkaline (NiMH rechargeable batteries can also be used, battery life will be reduced by up to 75%) |

|

| Accuracy of Setting | ±5% | |

| Dimensions | Without Wand – 210 x 42 x 37mm (8.3 x 1.7 x 1.5″) | |

| Standard Wand – 175mm (6.9″) long (including sponge) | ||

| Flat Sponge 175mm – (6.9″) long (including sponge) | ||

| Weight | 610g (21oz) including wand, cable, and batteries | |

| Certificate available | Certificate of Calibration: issued for Fixed Calibration equipment and shows readings and traceability | |

| Packing List | Pinhole Detector, standard wand, and flat sponge, 4m (13 2″) return lead with crocodile clip, 3 x LR1600 (AA) batteries, and operating instructions | |

Elcometer 270 pinhole detector – product accessories

- Roller Sponge Wand

- Spare Roller Sponge Set

- Standard Wand with Flat Sponge

- Spare Rectangular Sponges (Pack of 3) – 150 x 60 x 25mm (6 x 2.3 x 1″)

- Wetting Agent 50ml (1.7 fl oz)

- Separate Wand Adaptor with Belt Clip

- Telescopic Handle with Belt Clip – Extends to 1m (39″)

- 420mm (16.5″) Extension Piece

- 10m (32’10”) Signal Return Cable and Storage Drum

- 4m (13′) Earth Signal Return Lead

Can be used in accordance with:

AS 3894.2, ASTM D 5162-A, ASTM G6, ASTM G62-A, BS 7793-2, ISO 8289-A, ISO 14654, JIS K 6766, NACE RP 0188, NACE SP 0188, NACE TM0384

Monitor the integrity of the protective coating throughout its service life.

What makes Elcometer 270 so efficient?

- Ready to use

- Automatic sensitivity calibration and voltage checks

- Low battery indicator

- Visual/audible alarms

- Integral and separate wand functionality

- A wide range of fully interchangeable wand accessories

- Three model variants – single, dual, or triple voltages

- Easy-release snag-proof cables

- Large standard sponge

- An inspection kit for all your requirements is available

Pinhole Detector – Elcometer 270/3 Add to cart

Pinhole Detector – Elcometer 270/4 Add to cart

Pinhole Detectors Inspector’s Kit Add to cart

Pinhole & Porosity Detection

Premature corrosion of a substrate is usually due to the failure of the coating. A major cause of failure is the presence of flaws in the finished coating. Collectively referred to as a coating’s porosity the main types of flaw are described below:

Runs & Sags:

The wet coating moves under gravity leaving a thin dry film.

Cissing:

Occurs when a coating does not re-flow to cover the voids generated by air bubbles being released from the surface of a coating.

Cratering:

Occurs when the substrate is wet or if the coating has poor flow characteristics, thus creating voids in the coating.

Pinholes:

Caused either by air entrapment which is then released from the surface, or by the entrapment of particulates (dust, sand, etc.) that do not stay in place.

Over Coating:

If too much coating is applied to a substrate, as the coating cures it can crack from internal stresses of the coating. Under Coating:

Areas are not coated, or the coating flows away from particular edges, corners of a substrate and welds.

Furthermore over a rough surface profile, insufficient coating may leave the profile’s peaks exposed.

Testing for pînholes with the wet sponge method

Pinholes are caused by air entrapment, which is then released from the surface, or by the entrapment of particulates (dust, sand etc.) that do not stay in place. The Elcometer 270 range utilizes the wet sponge technique and has been designed to set a new standard for wet sponge pinhole detectors – a high-quality, low-voltage detector with similar accessories to a high-voltage spark tester. They are available both as an individual gauge and as pinhole inspection kit. Elcometer also offers the 260 UV Pinhole Flashlight for a quick, low-cost method of testing coatings for pinholes.

Pinholes are caused by air entrapment, which is then released from the surface, or by the entrapment of particulates (dust, sand etc.) that do not stay in place. The Elcometer 270 range utilizes the wet sponge technique and has been designed to set a new standard for wet sponge pinhole detectors – a high-quality, low-voltage detector with similar accessories to a high-voltage spark tester. They are available both as an individual gauge and as pinhole inspection kit. Elcometer also offers the 260 UV Pinhole Flashlight for a quick, low-cost method of testing coatings for pinholes.

A low voltage is applied to a moist sponge. When the sponge moves over a coating flaw, liquid penetrates to the substrate and completes an electrical circuit, setting off the alarm. The wet sponge technique is suitable for measuring insulated coatings less than 500 µm or 20 mil on conductive substrates and is ideal for powder coatings and other coatings where the user does not wish to damage the coating.

how to use Elcometer 270:

| Model | Elcometer 270/4 Pinhole Detector | |

| Voltage | 9V, 67.5V, and 90V | |

| Maximum Measurement Range | 500µm (20mils) | |

| Sensitivity | 9V: 90kΩ ±5% 67.5V: 125kΩ ±5% 90V: 400kΩ ±5% |

|

| Battery Life (continuous use) | 9V: up to 200 hours 67.5V: up to 100 hours 90V: up to 80 hours |

|

| Battery Type | 3 x AA (LR1600) 1.5V alkaline (NiMH rechargeable batteries can also be used, battery life will be reduced by up to 75%) |

|

| Accuracy of Setting | ±5% | |

| Dimensions | Without Wand – 210 x 42 x 37mm (8.3 x 1.7 x 1.5″) | |

| Standard Wand – 175mm (6.9″) long (including sponge) | ||

| Flat Sponge 175mm – (6.9″) long (including sponge) | ||

| Weight | 610g (21oz) including wand, cable, and batteries | |

| Certificate available | Certificate of Calibration: issued for Fixed Calibration equipment and shows readings and traceability | |

| Packing List | Pinhole Detector, standard wand, and flat sponge, 4m (13 2″) return lead with crocodile clip, 3 x LR1600 (AA) batteries, and operating instructions | |

Elcometer 270 pinhole detector – product accessories

- Roller Sponge Wand

- Spare Roller Sponge Set

- Standard Wand with Flat Sponge

- Spare Rectangular Sponges (Pack of 3) – 150 x 60 x 25mm (6 x 2.3 x 1″)

- Wetting Agent 50ml (1.7 fl oz)

- Separate Wand Adaptor with Belt Clip

- Telescopic Handle with Belt Clip – Extends to 1m (39″)

- 420mm (16.5″) Extension Piece

- 10m (32’10”) Signal Return Cable and Storage Drum

- 4m (13′) Earth Signal Return Lead

Can be used in accordance with:

AS 3894.2, ASTM D 5162-A, ASTM G6, ASTM G62-A, BS 7793-2, ISO 8289-A, ISO 14654, JIS K 6766, NACE RP 0188, NACE SP 0188, NACE TM0384

0 items

0 items