Elcometer 270 and the Wet Sponge Method

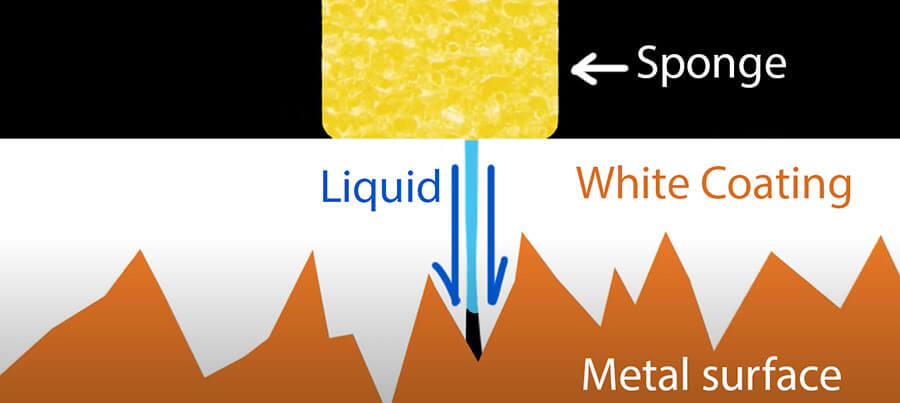

Use the low voltage pinhole method to test pinholes on thin coatings, powder coatings and other surfaces where you do not wish to damage the coating. This is a quick and simple method for surfaces – 500 microns (20 mils). A low voltage no bigger than 90 volts is applied to a damp sponge. Liquid from the sponge is drawn to pinholes by capillary action. This completes a low voltage circuit, setting off an alarm.

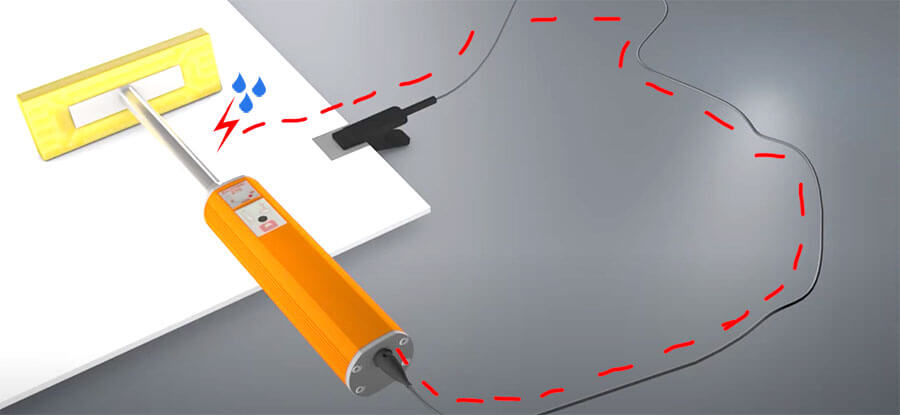

To begin, connect Elcometer 270’s signal return cable to an uncoated part of the substrate with a crocodile clip. A 4m or 10m signal return cable is provided. Next, wet the sponge with clean tap water, as it contains salts that allow it to conduct electricity.

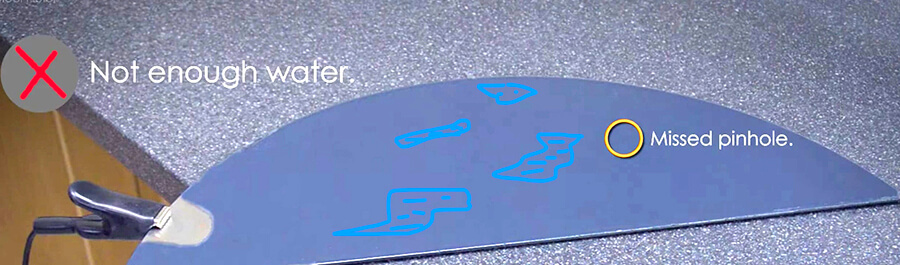

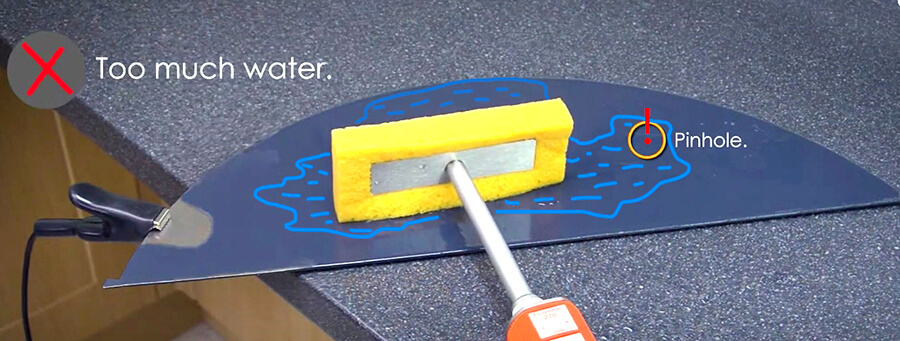

Note: too little water will not conduct well; too much water will drip and result in pinholes being detected in the wrong location. Please make sure the sponge is damp, but water is not dripping freely from it. To maximise the efficiency, you can add a surfactant to the water. This will reduce the water surface tension, allowing the moisture to penetrate into the smallest of pinholes. For how much to add, simply follow the dilution instructions supplied with the surfactant.

Switch on the Elcometer 270 – keeping the sponge clear of the test surface. If the sponge passes over a pinhole, the Elcometer 270 will instantly alarm. If you need to locate a pinhole more precisely, simply retest the area using just a corner of the sponge.

Elcometer 270 modes available

The Elcometer 270 is available in dual or triple voltage modes. The dual voltage model can be set to 9V, for coatings up to 300 microns (12 mils); and 90V, for coatings up to 500 microns (20mils). The triple voltage model can also test at 67.5V, the US standard test requirement. Every time the tester is switched on or the voltage is changed, the Elcometer 270 automatically tests the calibration of the internal voltage and sensitivity. With the calibration tested, you can now pass the sponge over the coated surface to test for pinholes.

Elcometer 270 accessories available

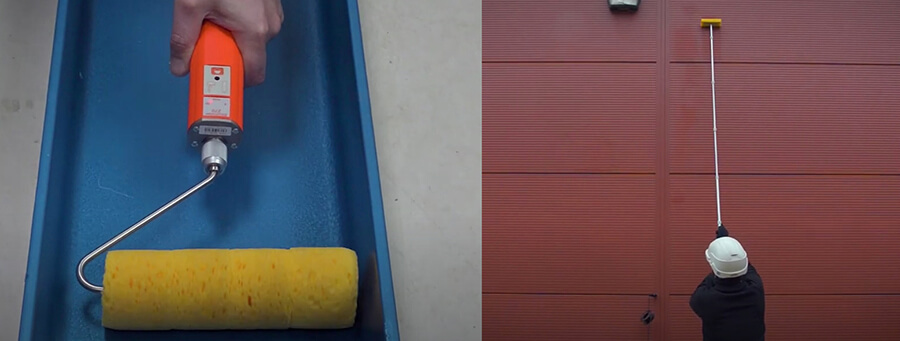

Elcometer 270 comes with a standard wand & flat sponge to suit most applications. However, there are a wide range of fully interchangeable accessories for different needs. The roller sponge wand is ideal for large, flat surfaces. A separate wand adaptor and belt clip converts the gauge into a separate pinhole detector. Use The telescopic wand adaptor ( 1m) for high areas, and connect further extension pieces. The Pinhole Detector Inspector’s Kit includes various wand adaptors, spare sponges, surfactant, and a 10m signal return cable. Simply choose your preferred model of Elcometer 270, and you have everything you need for low voltage flaw detection.

Testing on coatings up to 500 microns (20 mils) thick, the Elcometer 270 is the ideal gauge for detecting pinholes.

0 items

0 items